Focus Area: Coating and Corrosion Prevention

Contact

Joe Laws

joe@greay-gecko.com

757-813-4928

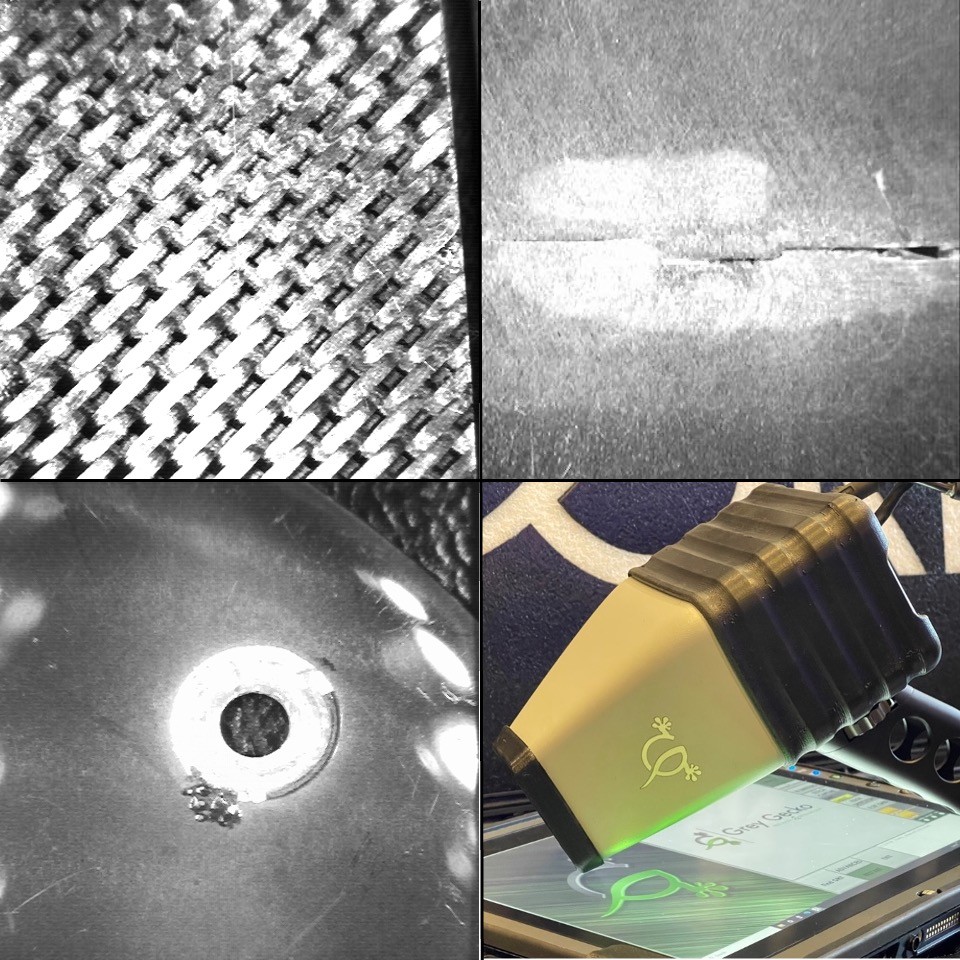

The Grey Gecko Real-Time Inspection Tool (GRIT) 125v2.50 is a patented corrosion detection device that optimizes Non-Destructive Inspections and offers a “first look and early find” capability, saving time and money. Developed and refined with feedback from the U.S. Coast Guard, Navy, Army, and Lockheed Martin, the deployable, lightweight, battery-operated device sees-through paint to the substrate. The GRIT can reduce aircraft downtime by 25% and inspection labor by 50% on commercial, strategic airlift, executive transport, aerial refuelers, C2ISR platforms, and 3rd/4th generation tactical and rotary-wing aircraft.

In Q4 2023, the Naval Air Warfare Center Aircraft Division’s Materials Engineering and Structures Engineering branches and the Jacksonville Materials Engineering Laboratory investigated and demonstrated the GRIT’s efficacy. Ideal applications are: uncoated, chromate and polyurethane systems, CARC, and epoxy non-skid, up to a thickness of 20mils. Eye-safe and FCC-compliant, the GRIT is equally effective on any substrate type with no PPE or PMEL. Recently, the GRIT system detected a crack on the rear horizontal stabilizer of a U.S. Coast Guard C-27J Spartan aircraft and two additional cracks that had evaded previous NDI inspections. This real-time inspection prevented the need for chemically removing the coating system.

Grey Gecko Real-Time Inspection Tool (GRIT)

Problem Statement:

Aircraft corrosion costs the DOD $20 billion annually while simultaneously performing critical airframe life extension programs to meet increasing national security requirements. Current NDI inspections are labor intensive, non-targeted, and inconsistent, relying heavily on the technician’s availability and tradecraft. The DOD needs a cost-effective, deployable, intuitive, and consistent inspection device.

Technology Solution Statement:

The GRIT system is a deployable corrosion inspection device that offers live imaging through aircraft coatings to the substrate at a depth of 20mils. It is a field-proven, commercially available device that streamlines existing inspection processes by directing technicians to specific areas of concern. It is equally effective on all materials and works globally at temps between 0-120°F, the GRIT's design and features have been optimized through continuous maintainer and program manager feedback.

Benefits Statement:

The GRIT offers a fast ROI through labor, inspection and mitigation savings. With an ROI of five months at the intermediate level and two months at the MRO level, the GRIT optimizes technicians' "time-on-job," saving a minimum of 50% in labor. Additionally, the GRIT provides early corrosion detection and reporting, enabling fleet managers to proactively address maintenance needs, ensuring operational readiness and fleet resiliency.