MELD® is a solid-state large scale additive manufacturing and repair technology that does not melt the metal at any point in the printing process. Not melting the metal is the key difference between the MELD process and all other metal 3D printing processes.

There are 2 notable advantages to not melting the metal: 1) The metal is fully (100%) dense on the back end. 2) The metal can achieve forged properties.

These advantages enable MELD users to produce large scale near-net shape forgings at rapid rates and leverage them in their production processes to avoid long lead times regularly encountered when sourcing traditional forgings from overseas. This also allows manufacturers to shore up their domestic supply chain constraints. MELD Manufacturing Corporation (based in Christiansburg, Va) invented the MELD technology and manufactures machines that produce forged quality materials.

Focus Area: Advanced/Additive Manufacturing

Contact

Wes Downs

wes.downs@meldmanufacturing.com

619-433-9002

MELD – AFSD Printing

Problem Statement:

The government, OEMs, and Primes experience long lead times to source forgings from overseas. Forgings are used in critical applications and are essential to meet the needs of the warfighter. These long lead times create delays in the supply chain and impact downstream production timelines.

Technology Solution Statement:

The MELD technology is a new manufacturing process that enables the production of forgings at the point of need and eliminating long lead times. The cost savings and material savings can also assist in driving the business case for adoption. The MELD technology allows the government, OEMs and Primes to shore up gaps and pain points in the domestic supply chain.

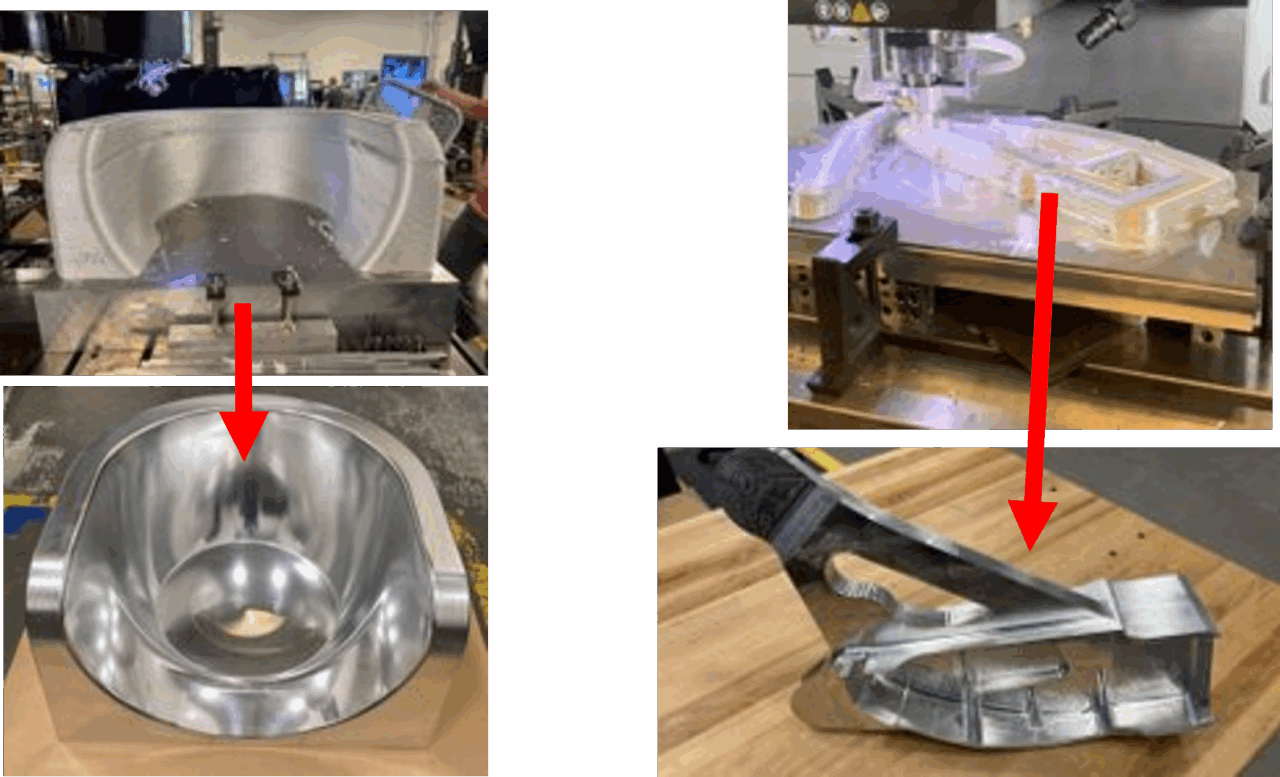

During the MELD process, a solid bar filler material is forced to flow between the rotating MELD tool and the substrate,

whereby the filler material undergoes severe plastic deformation, dynamic recrystallization, and deposition. Due to its additive nature, MELD can be used for coating, repair, joining, or additive manufacturing applications of both similar and dissimilar materials.

Benefits Statement:

MELD does not require the utilization of laboratory-grade equipment, such as vacuum chambers, laser and e-beam systems, or powder beds. The MELD technology was developed to overcome the above-mentioned shortcomings of these more traditional melt-based metal AM and repair processes. MELD Manufacturing Corporation’s proprietary MELD technology (Additive Friction Stir Deposition – AFSD) is a solid-state, thermo-mechanical AM process that yields fully-dense products with wrought properties, reduced distortion, high deposition rates, and significantly faster throughput as post deposition material-processing (HIP, sintering, etc.) is not required. MELD is differentiated from other AM technologies because it is a highly scalable, open-atmosphere process with a high deposition rate that offers flexibility with material sets and yields a wrought microstructure on near-net-shape complex 3D structures.

The MELD technology solves dependency on foreign suppliers, and lead time and supply chain challenges facing maintenance, lifecycle, new construction, and repair for the Navy and the respective industries that support the Navy’s needs. Because of this, MELD machines have been purchased by the US Army, Navy, Air Force and DOE.