Focus Area: Advanced/Additive Manufacturing

Contact

Rick Li

rick@prodexlabs.com

617-879-8810

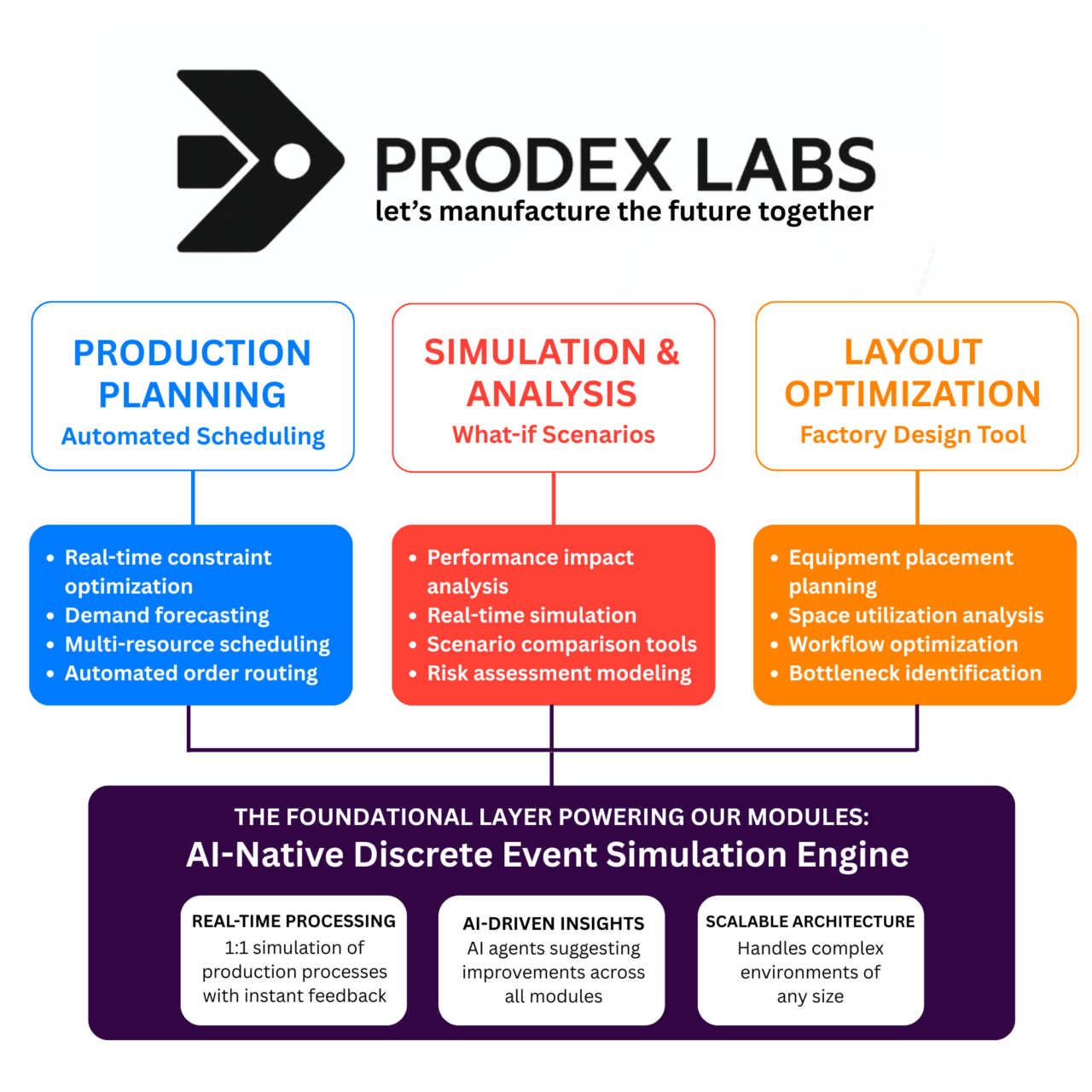

ProDex Labs delivers AI-native software tools that transform how manufacturers and sustainment facilities design, simulate, and plan production systems. Our integrated platform combines an AI-powered discrete event simulation with three core modules—what-if analysis, layout optimization, and production scheduling—enabling organizations to move beyond static spreadsheets and manual processes toward dynamic, data-driven decision-making.

With ProDex, engineers rapidly model factory workflows, optimize layouts within physical constraints, and generate production schedules in minutes. This accelerates job turnaround, reduces overhead, and provides real-time visibility into bottlenecks and inefficiencies. Unlike traditional planning tools, ProDex facilitates virtual iteration and validation before committing capital or labor. Powerful AI agents further dissect, analyze, and continuously improve factories down to every datapoint.

Already deployed at manufacturing sites from Massachusetts to Costa Rica, ProDex demonstrates commercial viability, operational scalability, and dual-use compatibility—particularly benefiting small and mid-sized manufacturers critical to the defense industrial base.

By embedding intelligent simulation and AI-driven scheduling into sustainment operations, ProDex enhances readiness, adaptability, and modernization across applications, from engine overhaul to munitions production. Built securely on flexible platforms like Palantir Foundry, ProDex accelerates planning and decision-making, creating a more resilient and responsive industrial base.

Smart Factory

Problem Statement:

Depot and industrial manufacturers face chronic delays, persistent inefficiencies, and resource strain due to reliance on outdated production design and manual planning methods. These challenges are especially acute for smaller factories and facilities integral to defense sustainment operations, where rapid reconfiguration is critical yet prohibitively costly. Static workflows, rigid layouts, and manual scheduling methods severely limit responsiveness to evolving mission requirements. To maintain readiness and competitiveness, manufacturers urgently require digital tools capable of accelerating planning, virtually simulating production changes, and dynamically optimizing floor layouts—significantly improving throughput, agility, and operational efficiency while reducing overall costs.

Technology Solution Statement:

ProDex is an AI-native, discrete-event simulation platform purpose-built for modern manufacturing and sustainment environments. Leveraging advanced AI and autonomous agents, ProDex rapidly optimizes workflows, intelligently adjusts layouts within real-world constraints, and generates executable production schedules in minutes. Integrated resimulation and agent-driven feasibility analysis accelerate confident decision-making without costly physical experimentation. Designed for minimal manual data entry and seamless interoperability with legacy or smart-factory systems, ProDex’s dual-use architecture directly addresses critical sustainment, readiness, and modernization challenges.

Benefits Statement:

ProDex significantly accelerates throughput, cuts planning times, lowers operating costs, and enhances agility across manufacturing and sustainment operations. Integrating simulation, layout optimization, and scheduling, ProDex leverages advanced AI agents to continually analyze, optimize, and refine every step of production workflows—enabling rapid adaptation to changing labor, equipment, material, and spatial constraints. Commercially proven, ProDex reduces weekly planning workflows from over 20 hours to under 30 minutes, ensuring immediate improvements in responsiveness, resource efficiency, and operational readiness.