Focus Area: Advanced/Additive Manufacturing

Contact

Angela Desmond

adesmond@rndautomation.com

252-229-2455

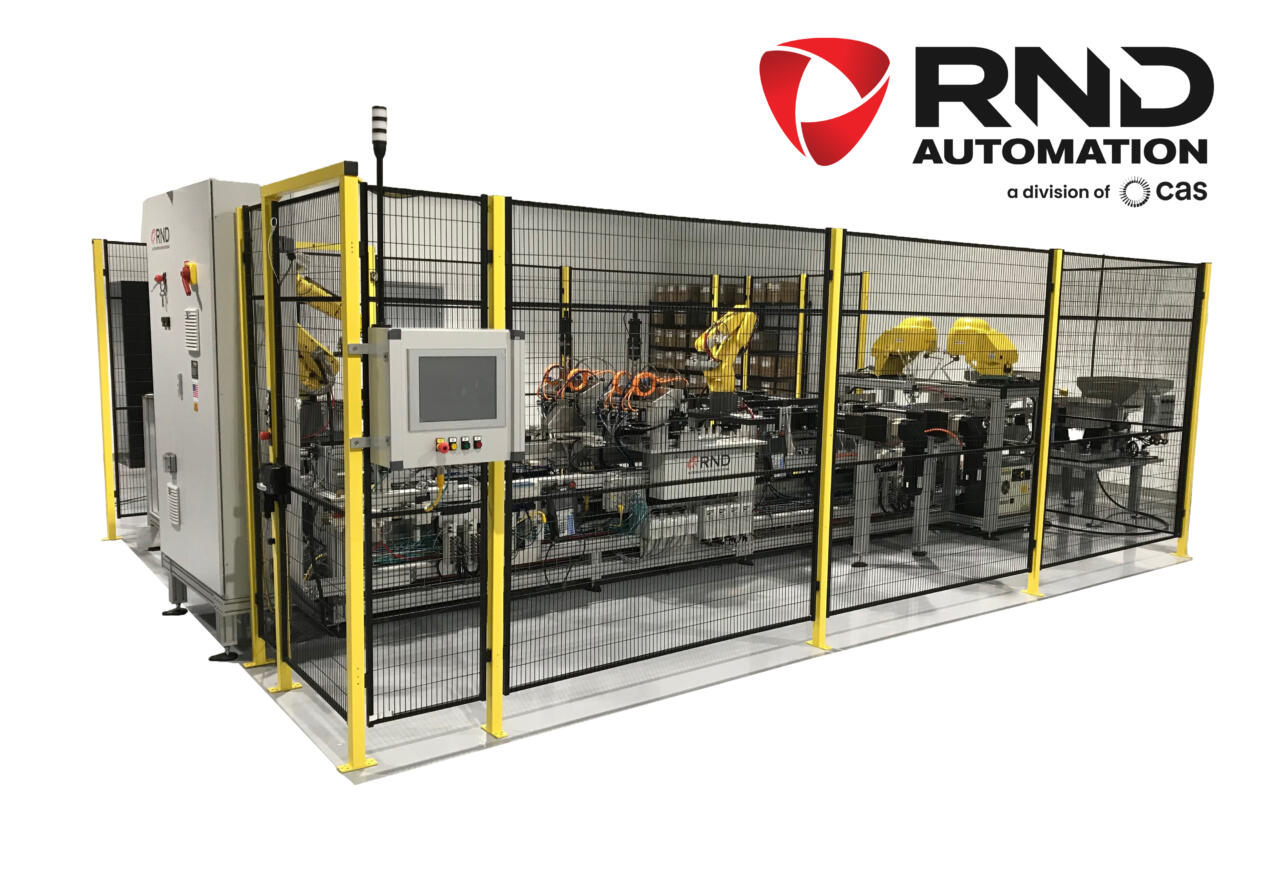

RND Automation is a leading provider of custom automation solutions specializing in the design, engineering, and integration of robotic systems, assembly automation, and packaging equipment. While we specialize in robotic automation that’s accessible to manufacturers of any size, RND serves a diverse range of industries including consumer products, aerospace, defense, automotive, medical device manufacturing, pharmaceuticals, food and beverage, and personal care. We are a Level IV Authorized System Integrator for FANUC Robotics, a Platinum Level System Integrator for Epson Robotics, and a Certified System Integrator for Universal Robots, as well as cooperation’s and expertise with Kuka, Kawasaki, ABB, and others. We bring extensive expertise in implementing robotic solutions across diverse applications.

Our core capabilities include robotic part handling, small-part assembly, precision dispensing, gluing, labeling, welding, vision inspection, automated packaging, modular platforms, and custom machine development. We excel in delivering solutions that increase throughput, improve quality, and reduce labor dependency all while offering scalability. We operate with a consultative, problem-solving mindset. We partner closely with customers to understand their specific challenges and develop tailored systems that align with their goals, timelines, and return-on-investment expectations.

Advanced Robotic Automation Systems

Problem Statement:

- Solutions to combat rising labor costs, lack of skilled labor, and workforce shortages.

- Address inconsistent product quality due to manual processes.

- Complex assembly tasks require specialized expertise and consistent execution.

- Increased demand for more flexible automation solutions.

- Having creative approaches to improve ROI on capital equipment.

Technology Solution Statement:

RND Automation delivers custom engineered robotic, assembly, and packaging systems that streamline production, reduce labor dependency, and improve quality. Our flexible solutions integrate seamlessly with existing operations and are designed for scalability. With advanced technologies like vision systems, robotics, and precision motion control, we enable manufacturers to boost efficiency, ensure consistency, and achieve rapid ROI.

Benefits Statement:

- Consistent & Improved product quality with precision automation and vision inspection.

- Enhanced workforce utilization allowing labor to focus on more challenging issues.

- Minimized downtime with robust, low-maintenance systems.

- Improved worker safety through automation of hazardous or challenging tasks.

- Increased overall production and throughput.

- Military grade encryption for remote diagnosis and equipment service.