TurnAround Factor (TAF) is a small business based in Richmond, Virginia that provides engineering consulting and R&D services. We are experts at developing new ideas and creating prototypes that can be tested with the user and ultimately transitioned to the field. We have an extensive team of engineers and developers that support a variety of federal customers. Our team is evenly split between developers, electrical engineers, and mechanical engineers, allowing us to bring an effective multidisciplinary approach to produce complex systems. Over 80% of our staff are engineers or developers including most of our senior leadership. Our multidisciplinary team allows us to effectively deliver technologies from the lab to the field. We strive to provide robust, practical solutions that can withstand the realities of field operations. TAF also provides manufacturing support services for low rate initial production and specialized parts at our assembly facility in Ashland, VA. Our team has reverse-engineered and modernized several legacy systems for critical nuclear enterprise systems. We also currently support several DLA and Navy activities.

Focus Area: Enhanced Inspection

Contact

Chris Richardson

chris.richardson@turnaroundfactor.com

804-404-6756

SME Connect

Problem Statement:

Many battle damage assessments, repair, and maintenance functions require depot maintenance or fly-away teams that might not be possible to provide when a near-peer adversary is denying access to the area that needs the repairs.

Technology Solution Statement:

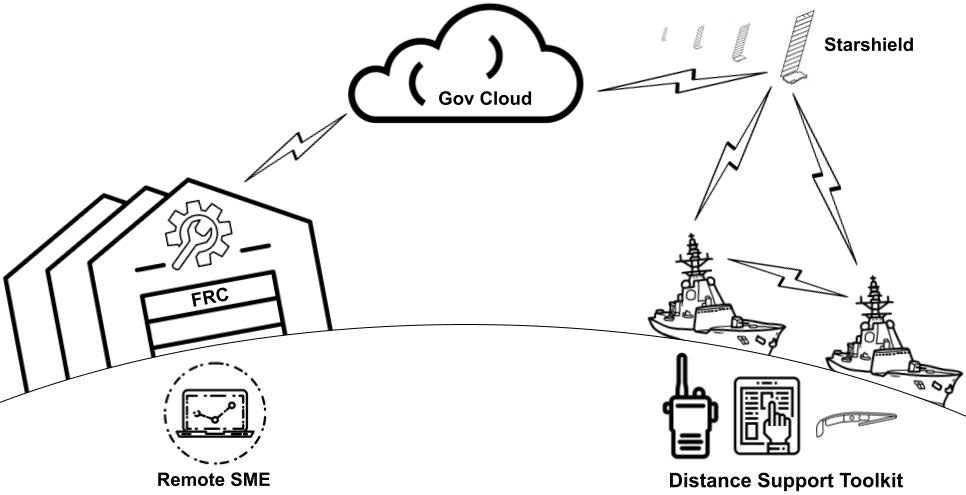

SME Connect allows sailors and marines shipboard or at remote locations to receive engineering assistance and support from engineers and technical experts at the ESAs and Fleet Readiness Centers. It also improves Maintenance Activity, creating a flexible, extensible framework allowing for deployable hardware and software capability packages.

SME Connect is an all in one solution that allows on-site users to interact with remote experts in an AR environment. The system provides remote access to specialized

tools and diagnostics by the remote expert(s) while in use by the on-site user. Tasks can be assigned and triaged, documents and workflows are shared, and the flexible framework for the system will greatly speed adoption of moving a growing range of maintenance processes further forward. Work instructions and document review can be carried out and connectivity and custom tool measurement is handled with SME Connect. This approach minimizes initial specialized equipment and allows the Navy to hit the ground running with immediate wins of new capabilities and operational efficiencies.

Benefits Statement:

Against peer adversaries that disrupt our logistical tail and require forces to operate on their own, the Distance Support Toolkit provides the warfighter access to the best engineering resources to undertake complex repairs and create field expedient repairs that meet safety and operational requirements. The Distance Support Toolkit enables the Subject Matter Experts (SMEs) to get closer to the equipment in operation, virtually on a moment’s notice, to return it to operation faster. The toolkit saves valuable time repairing and maintaining equipment, along with the costs of sending SMEs to location. The toolkit also allows for remote access to specialized tools and diagnostics equipment in use by the field user, with the work instructions and documents that they need. It also allows for depot level repair and maintenance tasks to occur in active operations against peer adversaries, saving valuable time and resources and greatly improving efficiency.

SME Connect improves maintenance activity by bringing remote tools and the virtual presence of a depot level SME to the equipment instead of having to wait to return the equipment back to depot. SME Connect can also be used with any U.S. partners or allies over the internet or other networks to provide them with the same level of support as they would get in a depot in the U.S. during their maintenance and repair training. Support for live translation is in development by TAF under an IR&D effort. The Distance Support Toolkit has been tested over Sat Comm and can be used anywhere the sky can be seen.