Focus Area: Workforce Development/Visualization

Contact

Shrikant Yarlagadda

shrikant@vieaura.com

312-882-7235

What if a young Marine could perform expert-level maintenance on complex military equipment like an expert – with zero prior training? Vieaura Inc. has cracked the code to address this challenge. Its AI-powered technology specializing in No-Code AI & AR platforms that transform complex maintenance, inspection, and training operations across defense and industrial sectors. Our solutions integrate advanced artificial intelligence, augmented reality, and computer vision to deliver context-aware work instructions and automated decision support systems.

Our primary customer base includes Department of Defense agencies (Navy, Marine Corps, Army, Air Force), manufacturing companies, and asset-heavy industries requiring enhanced operational efficiency and reduced training requirements. Through partnerships with Augusta University, the Georgia Tech Adv Manufacturing Inst. and NVIDIA Inception program membership, we combine cutting-edge research capabilities with proven commercial deployment experience.

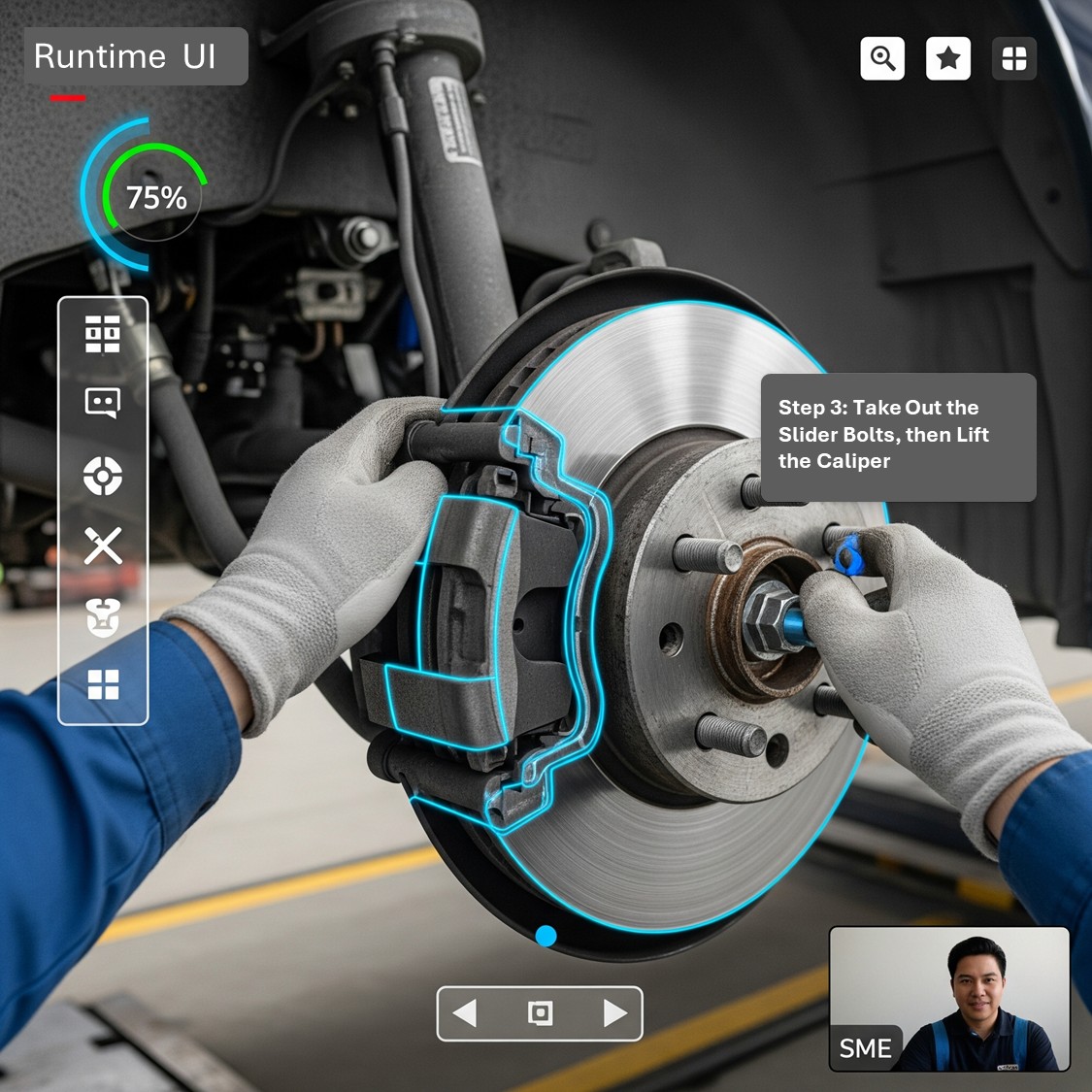

Key products include MENTOR (Maintenance Enhancement through Neural-assisted Technical Operations and Repair) for AR-guided maintenance, ShipLens for naval vessel inspection in mixed reality, RailSight AR for railroad infrastructure assessment, CommandSense for military decision support, ANDA for AI-enabled NEPA document assistance, and RACE for rapid adaptive course environment development. These solutions address critical challenges in knowledge transfer, operational readiness, and workforce development across the defense enterprise.

Want to see a live demo that will fundamentally change how you think about maintenance operations? Visit our booth. It will be time well spent. We look forward to helping transform your operations.

The AI That Turns Anyone Into A Maintenance Expert In Minutes

Problem Statement:

The military has a maintenance expertise crisis that’s getting worse:

- Complex equipment demands expertise that takes YEARS to develop

- Critical missions fail because the “one guy who knows how to fix it” isn’t available

- Training bottlenecks create operational readiness gaps

- 45% personnel turnover means constant skill drain

Bottom line: Our equipment is getting more complex while our workforce is becoming less experienced. This isn’t sustainable. We needed a breakthrough, not an improvement.

Technology Solution Statement:

We built an AI that downloads 30 years of maintenance expertise directly into anyone's brain through AR:

- Scalable computer vision recognizes any component in real time (95%+ accuracy)

- AI overlays expert procedures directly onto physical equipment

- Remote experts appear virtually for complex scenarios

- One-shot learning adapts to new equipment in real-time

- Result: Zero-experience operators performing expert-level maintenance in hours, not months

It's like having the world's best technician standing next to every maintenance task.

Benefits Statement:

This isn't incremental improvement - it's operational transformation:

- Training Revolution: Expert maintenance capability in hours vs. months

- Mission Multiplication: Every operator becomes a maintenance specialist instantly

- Crisis Solution: Equipment expertise independent of personnel turnover

- Cost Devastation: Eliminates massive training programs while improving quality

- Process Auditability: End to end data capture powering AI Insights & analytics

- Strategic Advantage: Maintenance operations possible anywhere, anytime, with minimal personnel