Technology Title

Heico-Lock

Tech Focus Area

Reliability Improvement

Abstract

Problem Statement: Securing fasteners on aircraft structures are limited to a limited number of alternatives; safety wire, safety cable, and cotter pins. Not used are nylon insert nuts, distended thread nuts, to their inability to address vibration. Heico-Lock wedge locking washers are not considered due to the damage that they would impart to aluminum which would result in the potential for generation of stress cracks in the aluminum.

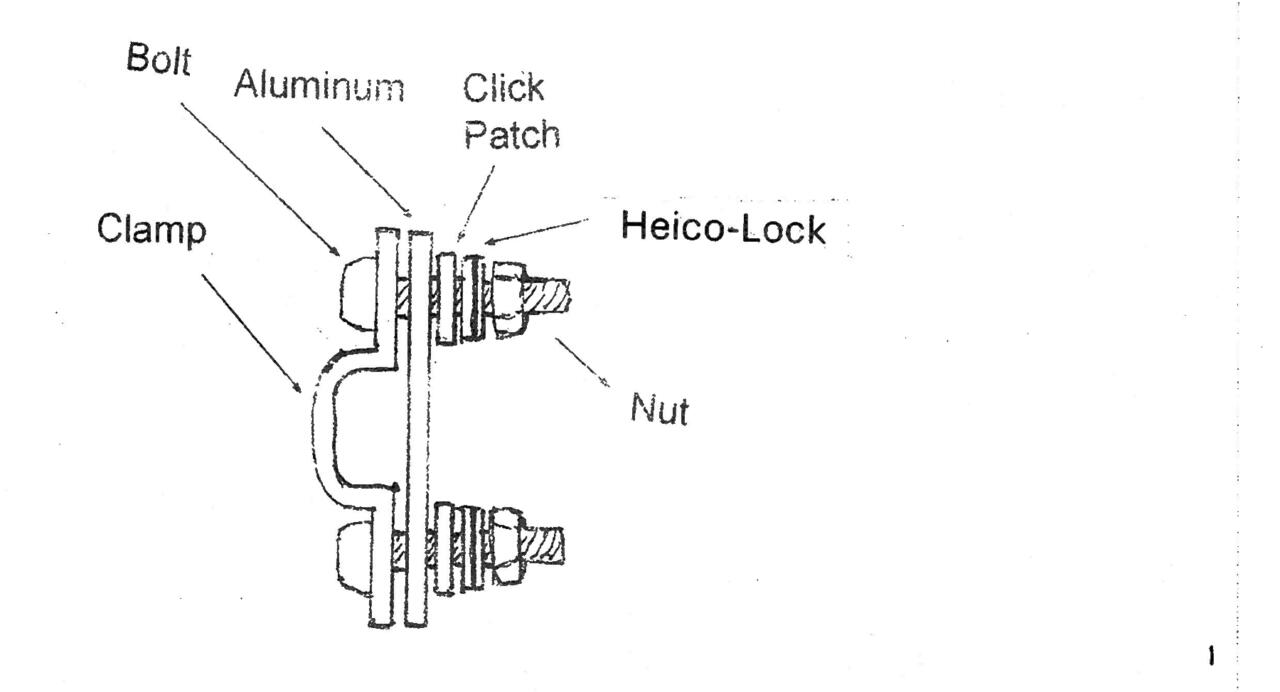

Proposed Innovative Solution: The solution involves the marriage of two existing technologies; the Enfasco "Click Patch" with the Heico-Lock wedge locking washers. The "Click Patch" is accepted technology as is the adhesive used to bond it to aluminum. The modification to the "Click Patch" would be adding a hole in the center of the patch through which a threaded fastener would pass. The modified patch would be bonded to the aluminum, a removable plug would hold the patch in place until the adhesive sets. The Heico-Lock washer rests on the patch which would absorb the indentations from the Heico-Lock washer and provide a secure method of bolt locking.

Benefits to the DOD: This solution would provide a alternative solution to bolt securing in areas of the airframe where space is limited or use of lock wire or locking cable is difficult. The solution is also re-usable and eliminates the potential of FOD hazards from safety wire pieces from either the installation or removal process.

Innovation Challenges: Testing, two steps – Proof of concept followed by intense vibration testing.

Proof of Concept: Fabricate a bolted joint with a section of aluminum drilled to accept a ¼" and a ¾" stainless steel bolt, install and bond two patches – one for each bolt size. Install one bolt of each size with a wedge locking washer in contact with the patch, torque to a standard torque for the bolt size. Disassemble and examine the aluminum for damage. If no damage is observed, proceed to vibration testing.

Intense vibration testing: Assemble several bolted joints that simulate bolted joints as they might be used on an airframe. Conduct vibration testing per DIN 65151, DIN 25201-4, or NASM 1312-7.

Technical Maturity/Demonstration Results: This has not been accomplished as there is test plan and funding required. Additionally, there are other configurations to be looked at to include bonding the wedge locking washers to the patch.

Graphic