4D Technology, an Onto Innovation subsidiary

Focus Area: Enhanced Inspection

Contact

Patricia Browne

patricia.browne@ontoinnovation.com

520-294-5600

4D Technology is the leader in high-resolution surface, geometry and wavefront measurements for challenging locations and applications.

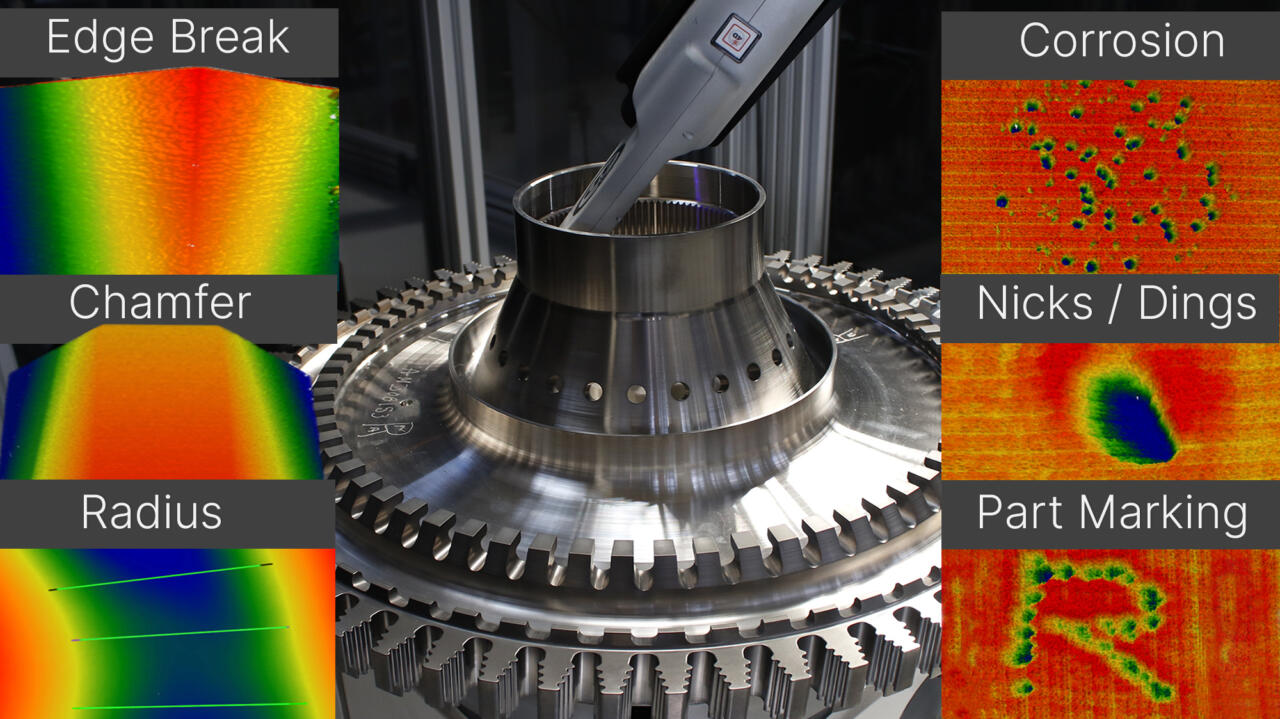

3D Optical Defect & Roughness Gauges

Problem Statement:

Performing precise, high-resolution measurements of defects and surface roughness directly on the shop floor or in the field—even on large parts and complex geometries—with exceptional accuracy and repeatability.

Technology Solution Statement:

The 4D InSpec uses patented vibration-immune technology to take rapid, repeatable, high-resolution surface measurements in challenging environments where there is vibration. This proprietary technology, referred to as Dynamic Interferometry®, allows for non-contact, 3D metrology to be used on shop floors and in the field for applications such as measuring defects and features on precision machined surfaces.

Benefits Statement:

The 4D InSpec delivers fast, accurate, and repeatable 3D surface measurements right on the shop floor or in the field—eliminating the need for replication or lab-based metrology.

- Increase yield by 20–40% by accurately measuring defects up to specification limits, enabling more parts to pass and reducing unnecessary scrap.

- Instant, non-contact 3D measurements of pits, scratches, nicks, dents, bumps, edge breaks, radii, and other features from 2 μm to 2.5 mm deep.

- Portable and rugged design for use on large parts and complex geometries in challenging environments.

- Micron-level resolution and high repeatability, outperforming visual inspection and tactile methods.

- Easy to use—one-button operation and intuitive touchscreen interface allow non-experts to take precise measurements within minutes.

- Flexible deployment: handheld, workstation, or robotic integration for automated inspection and high throughput.

- Comprehensive analysis and reporting with automatic defect detection, 3D visualization, and seamless data export to quality systems.

ALL-TEST Pro

Focus Area: CBM+/Predictive Maintenance

Contact

Mark Koch

mkoch@alltestpro.com

513-207-8529

ALL-TEST Pro is a worldwide leading manufacturer of electric motor predictive maintenance (PdM) equipment and condition monitoring tools. Since 1985, ALL-TEST Pro has provided the industry with the most advanced predictive maintenance (PdM) testing and troubleshooting tools for AC and DC motors, coils, windings, transformers, generators and more to a wide range of industries worldwide.

ALL-TEST Pro Energized and De-Energized Electric Motor Testing Equipment

Problem Statement:

- Unable to diagnose and separate a motor from a mechanical fault.

- Motors age, deteriorate, and can fail without notice

- Traditional tooling does not determine the full health of a motor.

- Unable to determine the condition of a motor system, leads to unnecessary maintenance, full replacement, or a shut down

Technology Solution Statement:

MCA finds both good & bad motors. ESA includes both power management and motor management of the entire motor system. ALL-TEST Pro instruments ensure that testing your motors is safe, easy, and dependable. Safeguard your operations that rely on electrical motors, variable frequency drives, transformer and generators with ATP instruments and software. ATP products help you maintain, schedule service, trend asset life, troubleshoot and diagnose your motors, thereby simplifying maintenance programs with accurate data for incoming motors, outbound repairs, safety concerns, scheduling maintenance, general operations & more.

Benefits Statement:

- Reduce wasted troubleshooting hours and unexpected downtime

- Field portable, light weight, battery powered, easy to operate, complete test in a few minutes

- Quickly diagnose the full motor system and pinpoint electrical and/or mechanical issues

- Improve/expand existing condition based monitoring (CBM) program

- Trend motor system health to improve planning and scheduling activities

Amazon Web Services

Amazon Web Services (AWS), the world’s most comprehensive and broadly adopted cloud, helps millions of customers around the world reduce costs, become more agile, and accelerate transformation with the most capabilities, the largest community, security they can count on, continuous innovation that ensures they always have what they need, and the most operational expertise that helps them build faster and with more confidence. AWS gives customers greater choice and flexibility by offering the broadest and deepest set of cloud capabilities to meet their specific needs. Choice and flexibility makes easier and more cost effective to move applications to the cloud and build nearly anything you can imagine. Security is our top priority. AWS is architected to be the most flexible and secure cloud computing environment available today. Our infrastructure is built to satisfy the security requirements for governments, global banks, and other high-sensitivity organizations. We work backwards from our customers’ needs, understand where they’re headed, and continually innovate to help customers move ideas to reality and accelerate transformation, today and in the future. AWS has the most operational experience, at the greatest scale, of any cloud provider, with unmatched performance, reliability, and guidance customers can depend on for your most important applications.

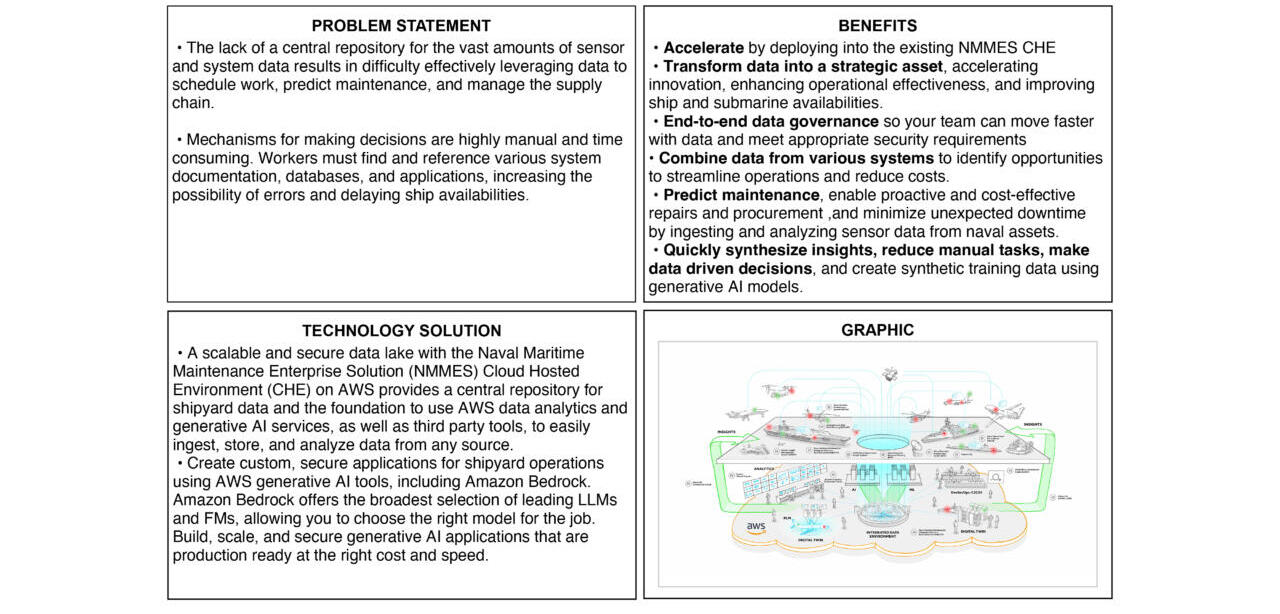

Advanced Data Analytics for Shipyard Optimization

American Ceramic Technology

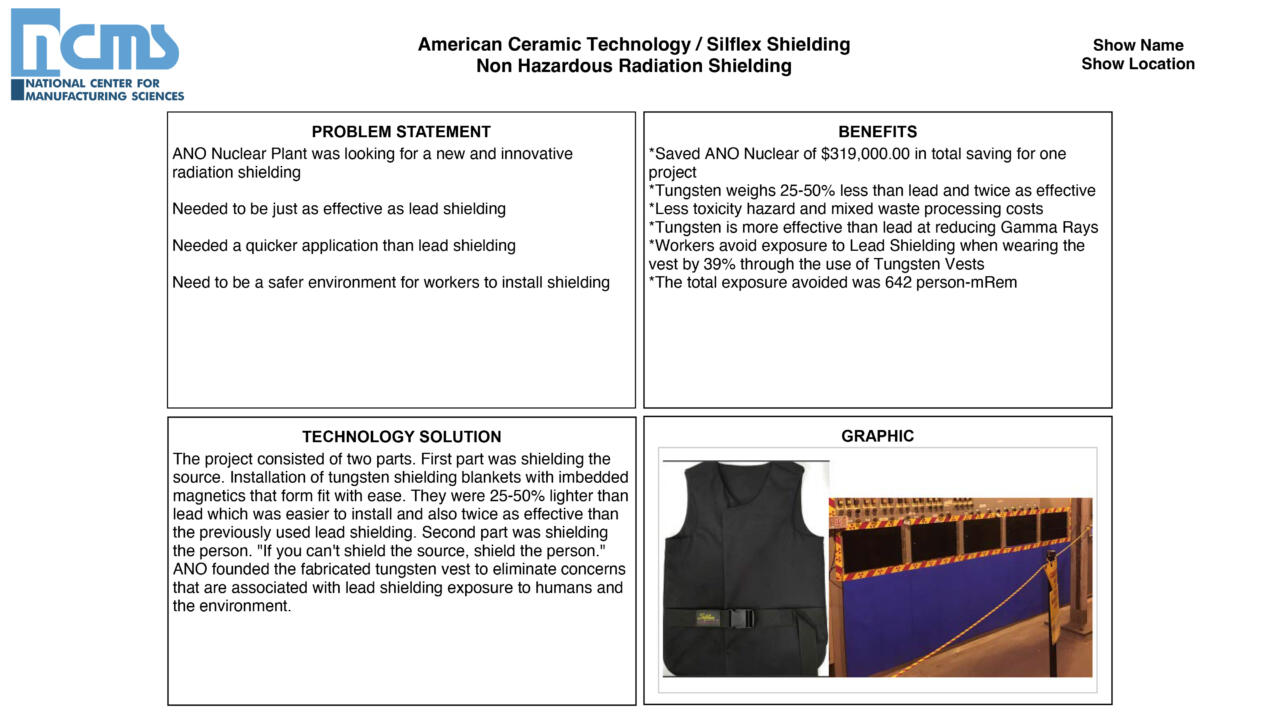

American Ceramic Technology, Inc. is the ISO 9001:2015 manufacturer of Silflex® Shielding, the award winning nonhazardous, non-lead radiation shielding. In 2005, Silflex® tungsten shielding was developed and certified by Entergy and ANO in 2007 for use in the nuclear industry. We have expanded into the medical, military, NDT, mining and oil & gas industries. Manufacturing is located in California and South Carolina. We have many radiation shielding materials and product options designed with a flexible silicone base. We design custom solutions to help customers achieve their ALARA goals. Silflex® shielding is designed for maximum radiation dose reduction during operation and installation to protect personnel and equipment. American Ceramic Technology’s innovative technology allows nuclear power plants, laboratories and naval reactors to provide a safer, cleaner and more efficient work environment.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Non-hazardous radiation shielding

Amphenol TPC Wire & Cable

Focus Area: Energy, Environmental, Health, and Safety

Contact

Dawn Zachary

dzachary@tpcwire.com

216-374-8395

Amphenol TPC Wire & Cable is a leading manufacturer of high-performance wire, cable, connectors, and assemblies engineered to perform in the harshest industrial and marine environments. With over 45 years of expertise, we deliver rugged, long-lasting solutions that reduce downtime, improve safety, and extend equipment life.

What We Do:

- Design and manufacture durable wire, cable, and connector systems built to withstand chemicals, extreme temperatures, flexing, and abrasion.

- Provide custom-engineered solutions to meet exact application needs.

- Deliver reliable, application-specific performance for mission-critical operations.

- Industries Served:

- Marine, Shipyard, and Naval

- Oil & Gas, Metals, and Mining

- Industrial Automation, Utilities, and Manufacturing

Why Amphenol TPC:

- Proven reliability and durability in demanding conditions.

- Expert engineering support and responsive problem-solving.

- Reduced maintenance and lower total cost of ownership.

- Commitment to innovation, performance, and customer success since 1979.

Key Products:

- Welding & Control Cables – High-flex, chemical- and abrasion-resistant solutions.

- Medium Voltage Cables – Safe, efficient power distribution.

- Terminated Cable Assemblies – Plug-and-play durability for rapid installation.

- Custom Storage & Deployment Systems – Engineered reel and enclosure solutions ideal for marine and shipyard environments.

- Amphenol TPC Wire & Cable — engineered for performance, trusted for reliability, and built to keep your operation connected.

High-Performance Wire, Cable, and Deployment Systems for Marine Environments

Problem Statement:

Power assemblies and welding cables in shipyard and marine settings face constant exposure to salt spray, moisture, abrasion, impact, and reeling tension.

Poor storage or deployment systems lead to tangled or damaged cables, causing costly downtime and safety risks.

Vessel shore-power connections often rely on generic assemblies that fail to deliver reliable, weather-resistant performance under harsh marine conditions.

The movement, storage, and use of large, heavy electrical cables or cable reels create a worksite safety risk for employees and contractors.

Technology Solution Statement:

Our integrated systems combining custom-engineered reel enclosures and cable reels with marine-rated, MILC24368/1 shore-power assemblies or ruggedized weld cable assemblies to address these challenges. The custom reel enclosures offer tailored size, material and deployment features for organized rapid cable deployment. The cable assemblies provide a weather-sealed, corrosion-resistant interface, designed specifically for demanding marine environments.

Benefits Statement:

- Organized cable storage and deployment via enclosures reduces tangles and damage, improving uptime.

- Rugged shore-power assemblies rated for marine conditions deliver reliable connections, reducing risk of failure.

- Customizable system allows specification of enclosure materials, cable length, connector options — resulting in lower life-cycle cost and fewer modifications.

- Minimized downtime, enhanced operational safety, and improved vessel connectivity in shipyard and marine environments.

- Properly specified cable types and cable management systems improve worksite safety and protect personnel from both physical ergonomic or electrical hazards.

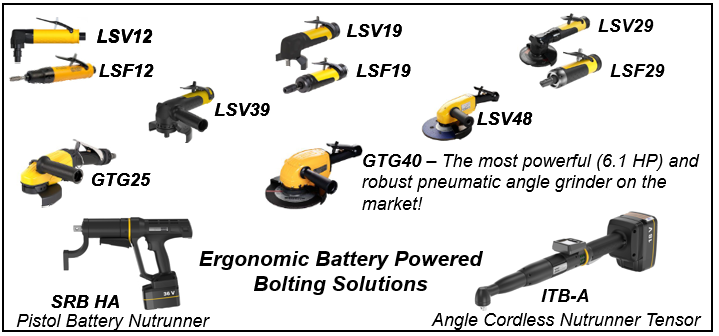

Atlas Copco Tools & Assembly

Focus Area: Advanced/Additive Manufacturing

Contact

Keith Herbster

keith.herbster@atlascopco.com

248-613-4430

Atlas Copco Tools & Assembly Systems (ACTA) is a global leader in industrial assembly solutions, specializing in smart, connected tools and engineered systems that drive productivity, quality, and sustainability. Our portfolio includes advanced tightening tools, torque and angle analyzers, error-proofing systems, machine vision, and software platforms that support Industry 4.0 transformation.

At our North American Applications Center (APC) in Auburn Hills, Michigan, we design and deliver custom-engineered solutions tailored to the unique needs of defense, aerospace, automotive, and heavy manufacturing sectors. Our high-performance teams collaborate with customers to develop ergonomic, data-driven systems that improve operator safety, reduce rework, and ensure traceable quality.

ACTA serves a wide range of government and defense customers, including U.S. Navy shipyards, depots, and prime contractors. We are ISO 9001, 14001, 45001, and 17025 certified, and our PF8000 controller platform supports advanced analytics, remote diagnostics, and predictive maintenance.

As part of Atlas Copco’s global network, we bring decades of innovation and a commitment to sustainable manufacturing to every project. Our solutions are designed to meet the evolving demands of ship repair, sustainment, and modernization programs.Integrated Assembly Systems for Defense Sustainment

Problem Statement:

- Manual assembly processes lack traceability and repeatability

- High rework rates due to inconsistent torque application

- Limited visibility into tool performance and joint quality

- Ergonomic risks in shipyard maintenance environments

- Need for data-driven maintenance and predictive diagnostics

Technology Solution Statement:

- ACTA’s PF8000 platform delivers smart, connected tightening with full traceability

- ACTA 4000 analyzers provide torque/angle validation and SPC analytics

- Custom-engineered solutions from APC improve ergonomics and reduce operator fatigue

- Integrated software enables real-time monitoring, diagnostics, and predictive maintenance

Benefits Statement:

- 30% reduction in rework through validated tightening processes

- 25% improvement in operator efficiency via ergonomic tooling

- 100% traceability of torque and angle data for QA audits

- Supports ISO 17025 calibration and Navy maintenance standards

- Enables predictive maintenance and CBM+ compliance

- Reduces downtime and improves fleet readiness

Avathon Government, Inc.

Focus Area: CBM+/Predictive Maintenance

Contact

MaTyna Fessler

matyna.fessler@avathongov.com

618-946-0177

Avathon harnesses proven AI technology to bolster military readiness, improve decision advantage, and optimize defense operations. Backed by a decade of successful commercial deployments, we provide practical, readiness-focused solutions to upskill maintainers and leverage predictive analytics, partner with the armed forces to enhance domain awareness and decision making, and enable modernization of the defense industrial base by optimizing capital equipment uptime, predicting engine failures, and strengthening supplier quality control through advanced technologies like deep learning NLP, generative AI, and computer vision.

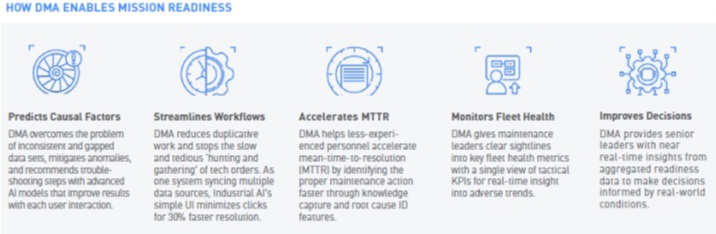

Digital Maintenance Advisor (DMA)

Problem Statement:

Declining mission-capable rates, skilled labor shortages, and increasingly complex systems are straining military maintenance operations. Slow workflows, parts delays, and limited supply chain insight degrade readiness and overload personnel – especially those with less experience.

Technology Solution Statement:

DMA applies explainable AI to deliver faster, smarter maintenance. It ingests structured and unstructured data to identify issues early, recommend actions, and surface parts availability – empowering maintainers to resolve problems quickly and accurately while providing leaders with actionable insights into fleet readiness.

Benefits Statement:

DMA enhances asset availability, reduces maintenance delays, and improves decision-making. It cuts resolution time by up to 30%, boosts maintainer confidence, and supports retention by simplifying tasks. Leadership gains near real-time insight into fleet health, enabling proactive, informed readiness decisions.

BlastOne International

Originally established nearly 50 years ago to provide technical consulting, BlastOne has grown to become a single source supplier of blasting equipment, abrasives and know-how to customers all over the world. BlastOne operates internationally from several offices across Australia, New Zealand, North America and Europe. We stand behind our brand claim of superior performance. It’s something we define as ‘Performance3’—the result of combining superior know-how with superior abrasives and superior equipment. In short, it delivers greater cost-efficiencies for our customers.

Focus Area: Coating and Corrosion Prevention

Contact

Brianna Cook

brianna.cook@blastone.com

614-695-5723

Blast & Coating Equipment

Problem Statement:

The blasting and finishing industry faces critical challenges, including manpower shortages, downtime from faulty equipment, environmental and dust concerns, and significant operator safety and health risks. Facilities are expected to deliver more productivity, cost efficiency, and safety, yet struggle with inconsistent performance and equipment reliability.

Technology Solution Statement:

BlastOne’s Velocity™ System is a game-changing advancement that integrates seamlessly into high-pressure production environments. It is engineered to alleviate short-term blast and coat bottlenecks by combining cutting-edge technologies like Intelliblast Blast Pot Controls, Snakebite Blasting Nozzles, and Vortex Airflow Movement. Together these components act as a force multiplier, delivering exponential gains in productivity, reliability, and environmental safety while addressing the industry’s most pressing challenges.

Benefits Statement:

BlastOne’s integrated solutions, including the innovative Velocity™ System, provide significant benefits by streamlining the blast and paint portion of production. This targeted approach reduces manual labor and enhances throughput in these critical processes. Proactive maintenance via BlastShield™ packages ensures reliable performance and minimizes downtime. Additionally, our solutions improve environmental outcomes and operator safety while supporting facilities in achieving their productivity and cost-efficiency goals.

Boston Engineering Corporation

Focus Area: Workforce Development/Visualization

Contact

Mark Smithers

msmithers@boston-engineering.com

508-259-8686

Boston Engineering is a leader in sustainable digital transformations, implementing innovative technologies, and developing road maps to solve tomorrow’s business challenges. Leveraging the latest in emerging technologies, such as Sustainment Robotics (SR), Augmented Reality (AR), Virtual Reality (VR), Internet of Things (IoT), and more, Boston Engineering helps you bring innovation to bear on your mission. Whether leading ideation, developing proofs of concept, building consensus, providing training, or handling post implementation support, simply Image the Possibilities and Boston Engineering will expand your capabilities to innovate.

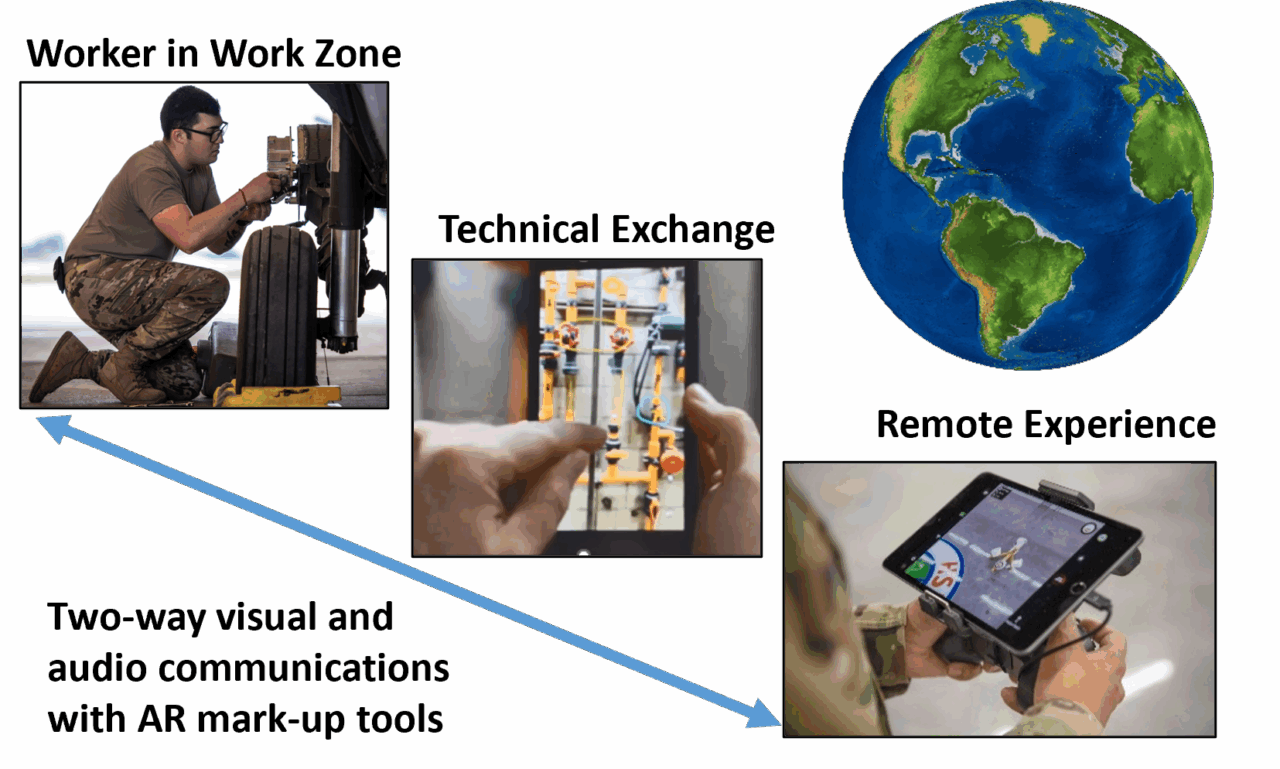

MREG

Problem Statement:

- Maintenance and sustainment of our weapons systems is being challenged by shrinking experienced workforce and increases in our national retirement rate.

- Nascent workers require training and mentoring before achieving the proficiency of highly skilled workers

- Nascent workers often experience work package execution issues and must leave the work site to seek advice or help with decisions enabling continued work execution

- Many maintenance requirements are discovered only after a weapon system reaches its destination. Knowledge gathering in route to the shipyard is not captured well today.

Technology Solution Statement:

- Mixed Reality Expert Guidance (MREG) is an Augmented Reality (AR) enhanced secure video remote assistance tool connecting experienced workforce to nascent workforce.

- MREG operates on premise, on cloud infrastructure, or in hybrid or mixed connected and unconnected configurations.

- The capability is built using open architecture, open standards, and software licensing to operate not required.

- MREG has been demonstrated on portable 5G communications ship-to-shore in port providing the necessary bandwidth to support video communications.

- MREG is device agnostic.

Benefits Statement:

- Provides experienced guidance to workers in work areas from experienced remotely located high skill or experienced workers and supervisors.

- MREG can record or actively share work assessments in the field in advance of shipyard stationing providing planners advanced information, resulting in reduced schedule.

- Connects nascent workers with retired workers who can work from home or part-time and continue sharing experience.

- Open architecture enables capability advancement contributions by multiple people and organizations in industry, academia, and DoD R&D Centers. Achieved TRL 7 demo

BrandTech by BrandSafway Solutions, LLC

Focus Area: Advanced/Additive Manufacturing

Contact

Eduardo Almeida

ealmeida@brandsafway.com

281-896-0507

BrandTech® by BrandSafway Solutions, LLC will demonstrate proprietary, computer-driven, software-enabled, precision stud welding, regardless of machine, environment or operator (welder).

With local branches ready to support across the U.S., Canada, and Europe, BrandTech® is ready for deployment and use at any shipyard where Ship Maintenance and Construction needs occur including Pearl Harbor, HI, San Diego, CA, Bremerton, WA, Jacksonville, FL, Norfolk, VA, or Kittery, ME. Reach out today! Welders everywhere will thank you!

BrandTech Computerized, software-driven, stud welding

Problem Statement:

BrandTech® Precision Welding produces stronger welds, with incredibly low rejection rates, in all conditions, and no human skill dependency.

- Welding of exotic materials without Pre-Heat

- Less than (<) 0.5% weld rejections

- Less than (<) 0.6% Hexavalent Chromium Exposure

- Not human-skill dependent

- Developed, designed, sourced, and manufactured in the USA

- UL 2900-2-2 Certified for Cybersecurity of Industrial Control Systems (ICS) by the National Security Agency (NSA)

Technology Solution Statement:

BrandTech® meets rigorous Quality and Reliability standards to match the strenuous demands of a Shipyard Workplace environment.

- State of the art components as per IEC, ROHS, UL, CE, FCC, and RU

- UL and CSA Listing – File No.: E501577

- Large inventory of equipment and consumables

- Global reach with local branch support

Benefits Statement:

BrandTech® produces significant cost reductions and time savings with no additional training requirements – minimal time to train operators (welders) for use.

- Fast installation and Single-Side Access: welders do not need to access the reverse side of the material

- No need for extra hardware: eliminates need for nuts, bolts, washers, and backing plates

- Precise welds reduce material waste and rework (<0.5% weld rejection rate)

- Less Downtime: Faster processes mean quicker turnaround times for ship sections

- Strong, reliable welds reduce the likelihood of failure, minimizing costly repairs

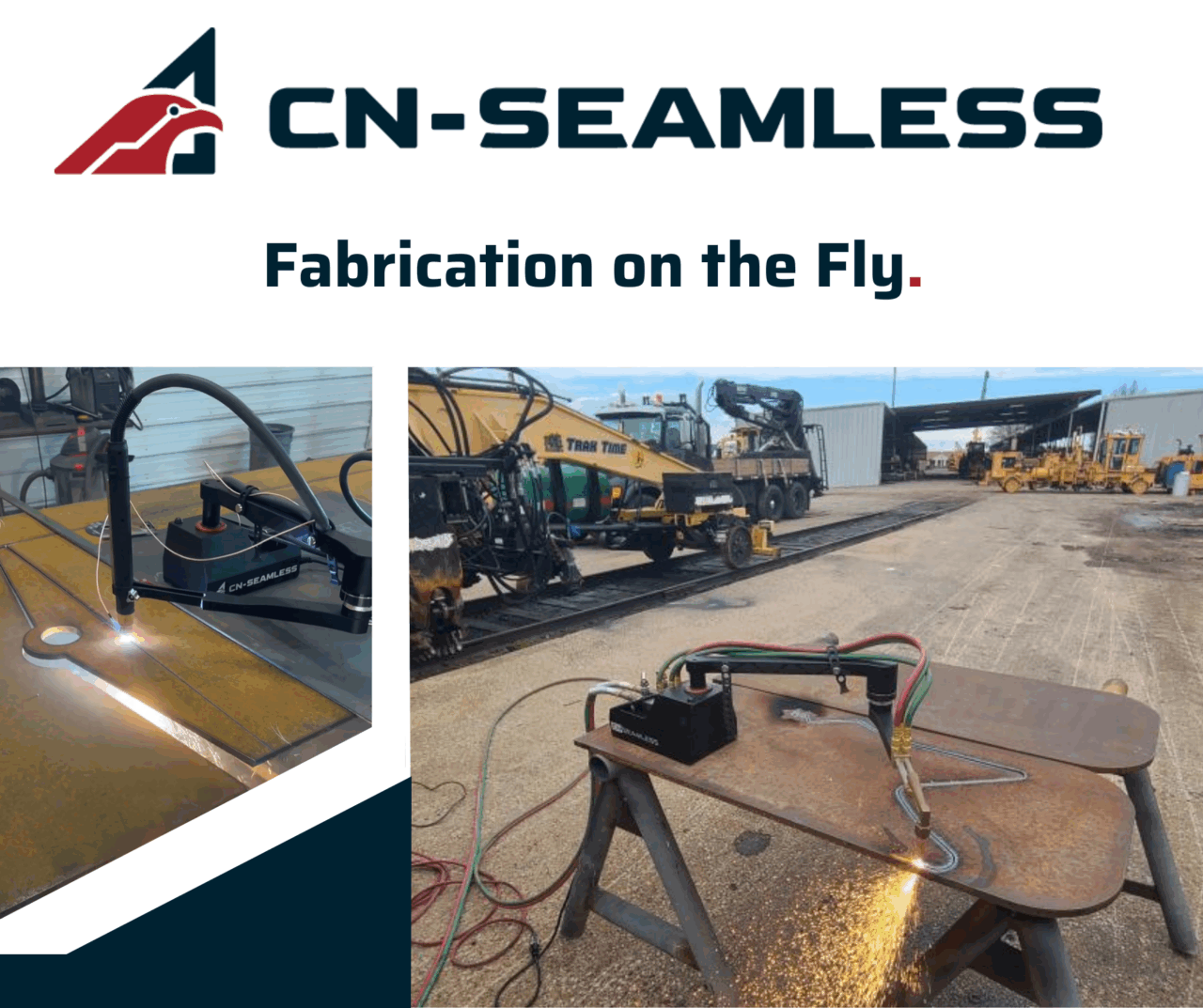

CN – Seamless

Focus Area: Advanced/Additive Manufacturing

Contact

Josh Cooper

josh@cn-seamless.com

919-636-0380

CN-Seamless is a North Carolina-founded technology company revolutionizing field fabrication and maintenance through compact, deployable automation systems. Our flagship product, the Mach 1, is a portable oxy-fuel and plasma cutting machine designed for use in austere environments by welders, maintainers, and fabricators. It enables precise metal cutting on flat plate, structural steel, and existing equipment—eliminating the need for stationary CNC infrastructure.

Deployable Automation System

Problem Statement:

The rapid maintenance and repair of large transportation assets, facilities, and operational support equipment is critical for mission readiness. Unlike commercial manufacturing, every repair within defense contexts is unique, reducing the benefit of automation compared to the time spent programming automated systems. Consequently, most maintenance still relies on the skill and availability of the maintainer. Unpredictable issues including battle damage, terrain hazards, mishaps, corrosion, or specialized mission demands force maintainers to spend time developing extensive maintenance projects, rely on depot repairs, or consider disposal.

Technology Solution Statement:

The Mach 1 is a portable, semi-automated fabrication platform that delivers powerful oxy-fuel and plasma cutting capabilities to any worksite, empowering maintainers, fabricators, and welders to perform precise cuts in metal with speed and consistency. Designed for rugged environments and rapid field deployment, the Mach 1 simplifies complex cutting tasks by automating manual processes typically reserved for heavy CNC equipment.

Currently under development, new end effectors for plasma blasting, welding, bevel cutting, 3D printing, and more will make the Mach 1 the ultimate automation system built for the field.

Benefits Statement:

The value of such a low-cost automation system that deploys directly to equipment and facilities being maintained is extremely high. The ability for any team in a base to perform rapid maintenance, fabrication, or repair with robotic precision specific to the tooling needed will drastically improve the decentralization of logistically complicated procedures. Gaining the ability to perform depot-level repairs on any base by bringing the Mach 1 to the equipment will result in millions of dollars saved in transportation costs alone. The portable nature of the Mach 1 means teams can become comfortable with the operation on base and have the ability to perform the same automated repairs while deployed. Furthermore, the end-effectors to be supported by the Mach 1 extend far beyond just maintenance use. Tactical breaching and rapid base construction and reconstruction are among the many additional potential benefits to having such a portable and easy to set up system.

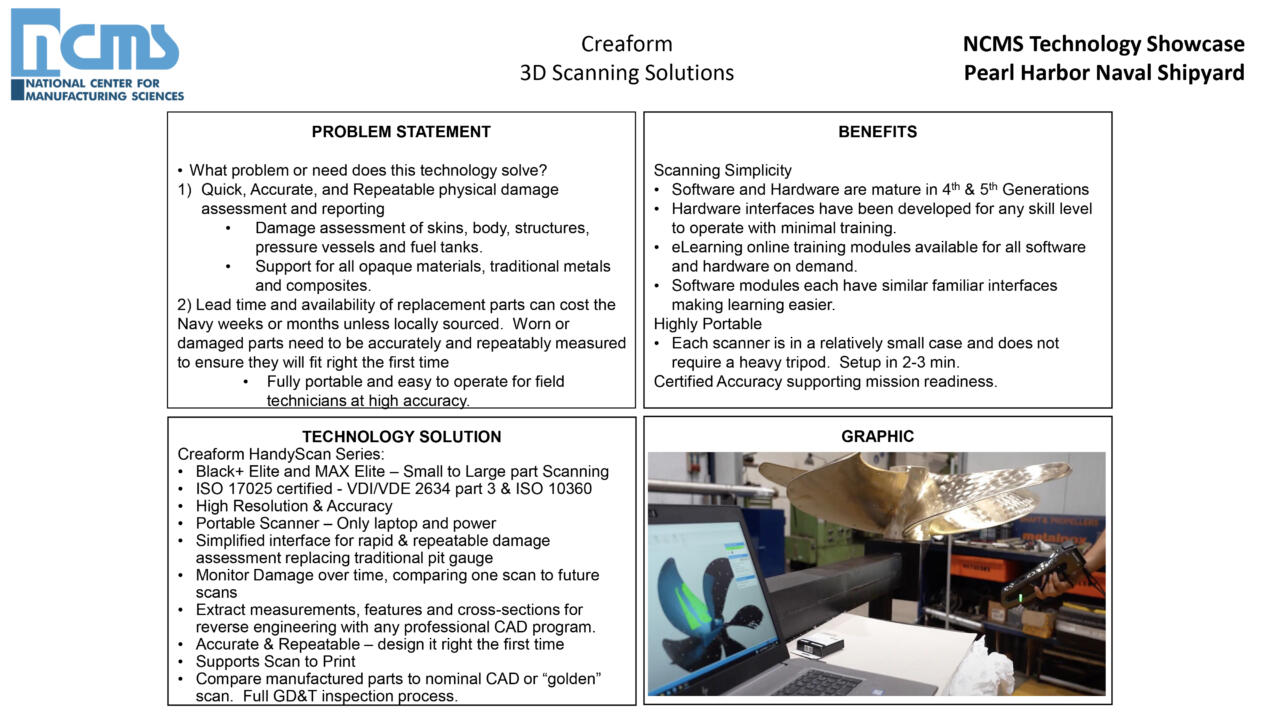

Creaform

Creaform develops, manufactures and markets cutting edge portable 3D measurement and analysis technologies that increase productivity. Creaform offers innovative solutions for applications such as 3D scanning, reverse engineering, quality control, non-destructive testing, product development, and numerical simulation (FEA/CFD). Its products and services cater to a variety of industries, including automotive, aerospace, consumer products, heavy industries, healthcare, manufacturing, oil and gas, power generation, research and education.

With headquarters and manufacturing operations in Lévis, Québec, Creaform operates innovation centers in Lévis and Grenoble France, and has direct sales operations in Canada, USA, Mexico, Brazil, France, Germany, Italy, Spain, China, Japan, Korea, Thailand and Singapore.

Creaform is a unit of AMETEK Ultra Precision Technologies, a division of AMETEK Inc., a leading global manufacturer of electronic instruments and electromechanical devices, with annual sales of approximately $4.0 billion.

Customers benefit from fast, accurate, repeatable measurements. Creaform technologies make it possible to measure in the real world without loss of accuracy.Focus Area: Enhanced Inspection

Contact

Mike Walsh

415.298.2432

mike.walsh@ametek.com

https://www.creaform3d.com/en

Creaform 3D Scanning Solutions

DMG MORI Federal Services

The DMG MORI Group is a leading innovator in the machine tool industry with an expansive portfolio of manufacturing equipment. We are focused on customer support, quality, service, and advanced technology. Our product line includes 5-Axis Milling machines, 4 and 5-Axis Horizontal Machining Centers, Additive machines, Hybrid machines, Vertical Machining Centers, CNC Turning machines, CNC Boring mills, and a variety of Palletized systems and Grinding machines. With over 12,000 team members world-wide, our group companies specialize in providing unmatched applications support, service and training to large OEMs, Tier-one contractors, and the US government itself. DMG MORI Federal Services (DMFS) works exclusively with US federal and State government agencies to support government initiatives while focusing on federal acquisition regulations and cybersecurity compliance. DMFS is also (ITAR) Registered, (CMMC) 2.0 complaint ready, and (NIST) compliant. We currently have active projects with the Army, Navy, Air Force, Department of Energy, and NASA.

Focus Area: Advanced/Additive Manufacturing

Contact

Kevin Pasiola

224.451.5137

kpasiola@dmgmore-fs.com

https://dmgmori-fs.com/

DMG MORI Advanced Manufacturing and Additive Manufacturing Solutions

Edlore

Focus Area: CBM+/Predictive Maintenance

Contact

Javid Vahid

javid@edlore.com

949-690-2245

Edlore is a pioneer in AI/ML and 3D technological solutions, reshaping industry standards with its interactive manuals and wearable device integrations. Our patented AI-driven platform transforms complex technical orders into digestible, contextually relevant insights, streamlining operations. With state-of-the-art mobile and wearable technology, professionals achieve access to crucial data, ensuring efficiency and precision. Our platform also encompasses a robust Work Order Management system, enhanced by asset tracking and multimedia attachments, facilitating seamless operations and maintenance processes. At Edlore, we blend innovation and practicality, consistently delivering excellence in an ever-evolving technological landscape.

Edlore AI-On Prremise server with 3D parts identification

Problem Statement:

Despite the rapid advancement in industrial and technical operations, complex equipment service and maintainers often grapple with cumbersome manuals, scattered asset data, and lack of real-time expert assistance. This disjointed information flow increases operational downtime and raises the margin for error.

Technology Solution Statement:

Edlore introduces a unified technology suite designed for the modern maintainer. Leveraging AI's power, we've transformed dense manuals into interactive, 3D-guided insights that intuitively provide the right information at the right time. Our platform, optimized for desktop, mobile and wearable devices, ensures hands-free, on-the-go access to these insights, minimizing downtime. Furthermore, with our real-time Remote Expert Video Chat, professionals are never alone in the field, always having a lifeline to expert assistance. Paired with a comprehensive Work Order Management system and dynamic asset tracking, Edlore's solution streamlines operations. A simple scan of a device will show all manuals, drawings, videos, pictures, LOTO Safety, PM procedures, Remote Expert Video Chat and 3D/AR explosive view with parts metadata that allows you to even send the part to be printed on a 3D printer.

Benefits Statement:

Empowering maintainers with immediate access to AI-enhanced, 3D interactive guidance, reduces operational errors and downtime. By unifying knowledge, expertise, and real-time tracking within a mobile and wearable interface, we ensure every task is executed with precision, speed, and confidence. The benefits of using Edlore are:- More efficient on-board service and repair.

- Never miss regular PM Maintenance.

- Access to device parts metadata and ability to possibly print the component on board.

- Gathering field data from service and repair.

- Mobile and handsfree operation.

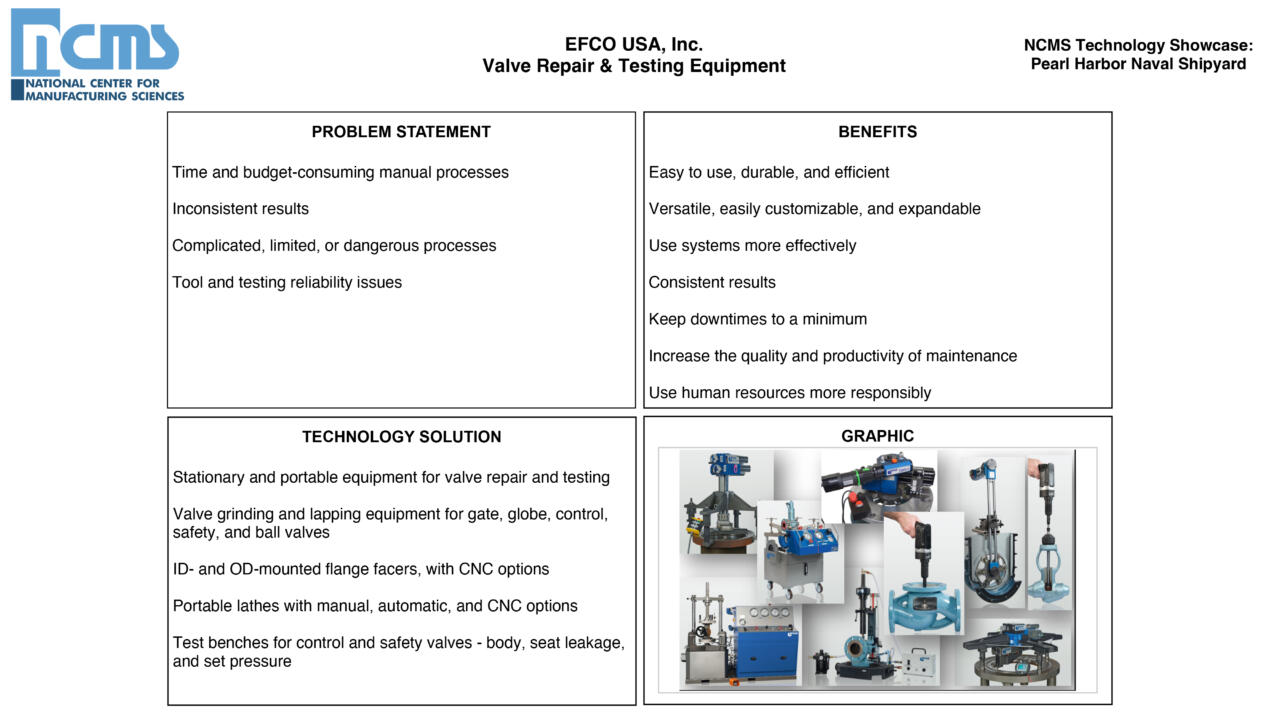

EFCO USA, Inc.

Established in 1978, EFCO has been a world-leading manufacturer of portable and stationary valve repair and testing equipment. Wherever fittings, valves, and pumps are used, EFCO equipment is also needed to maintain, repair, and test sealing surfaces, shut-off bodies, and housings. We are a family-run business with the philosophy of making our customers our partners – working together to create machining and testing solutions. Customer experience from the extensive use of our machines continuously contributes to our product development.

EFCO equipment is used worldwide, certified to DIN EN ISO 9001, and is characterized by our quality, durability, easy handling, and superior results. Our product range for in-shop and in-field service includes portable and stationary grinding and lapping equipment, flange facers, portable lathes, test benches, and workshops for valves, flanges, and pipelines. Our technically advanced tool line gives anyone repairing or maintaining valves the edge to improve valve maintenance fast and efficiently, resulting in cost-effective work with machines that last.

The EFCO USA Headquarters is located in Charlotte, NC and services Shipbuilding & Repair, Oil & Gas, Petrochemical, Energy, Shipyards, Valve Service and Manufacturing, and other industries in all of North and South America.Focus Area: Workforce Development/Visualization

Contact

Sales

800.332.6872

sales@efcousa.com

Valve Repair & Testing Equipment

FARO Technologies Inc.

Focus Area: Advanced/Additive Manufacturing

Contact

Patrick Baltes

patrick.baltes@faro.com

910-670-4098

FARO is the leading global source for 3D measurement, imaging and realization technology. For 40 years, FARO has provided industry-leading technology solutions that enable customers to quickly and easily measure their world and then use that data to make smarter decisions faster. FARO continues to be a pioneer in bridging the digital and physical worlds through data-driven reliable accuracy, precision and immediacy. FARO’s global headquarters is located in Lake Mary, Florida. The company also has a technology center and manufacturing facility located in Exton, Pennsylvania, containing research and development, manufacturing and service operations.

3D Laser Scanning, Reverse Engineering, Rapid Prototyping

Problem Statement:

- In order to stay competitive, you need to meet increasingly strict quality standards — and do this as cost-effectively as possible. You can’t invest in a quality control or inspection solution only to find out that it doesn’t perform as you expected, or that it requires significant changes to your team’s workflow, skills or software.

- Traditional Bridge style CMMs and other stationary measurement methods do not alone provide the mobility and versatility required by today’s manufacturing standards.

Technology Solution Statement:

- Sometimes a part or tool is so large or complex, you can't use stationary CMMs or Arm systems. FARO® VantageS6 Max and VantageE6 Max Laser Trackers enable you to build and inspect products by measuring quickly, simply and precisely with exceptional portability. The Vantage Max Laser Trackers offer comprehensive, large-volume 3D measurement up to 80 meters, significantly streamlining your processes and reducing inspection cycle times while ensuring complete confidence in the results.

- Vantage Max can incorporate our highly accurate 6 degrees of freedom (6DoF) measurement capabilities via the optional 6Probe, which enables precise measurement of hidden areas and small features.

Benefits Statement:

- Quick and simple inspection process

- Easy to use software with no programming required

- Fully portable and wireless, allowing it to be used in the field unlike a traditional CMM

- Can bring the device to your parts.

- Laser Tracker allows detailed measurements of complex geometry across a very large envelope (up to 80 meters)

- Easy to apply coordinate system means little to no prep time per part

- Ready to use right out of the box

- No manual data entry is needed - measurements are automatically stored in the software

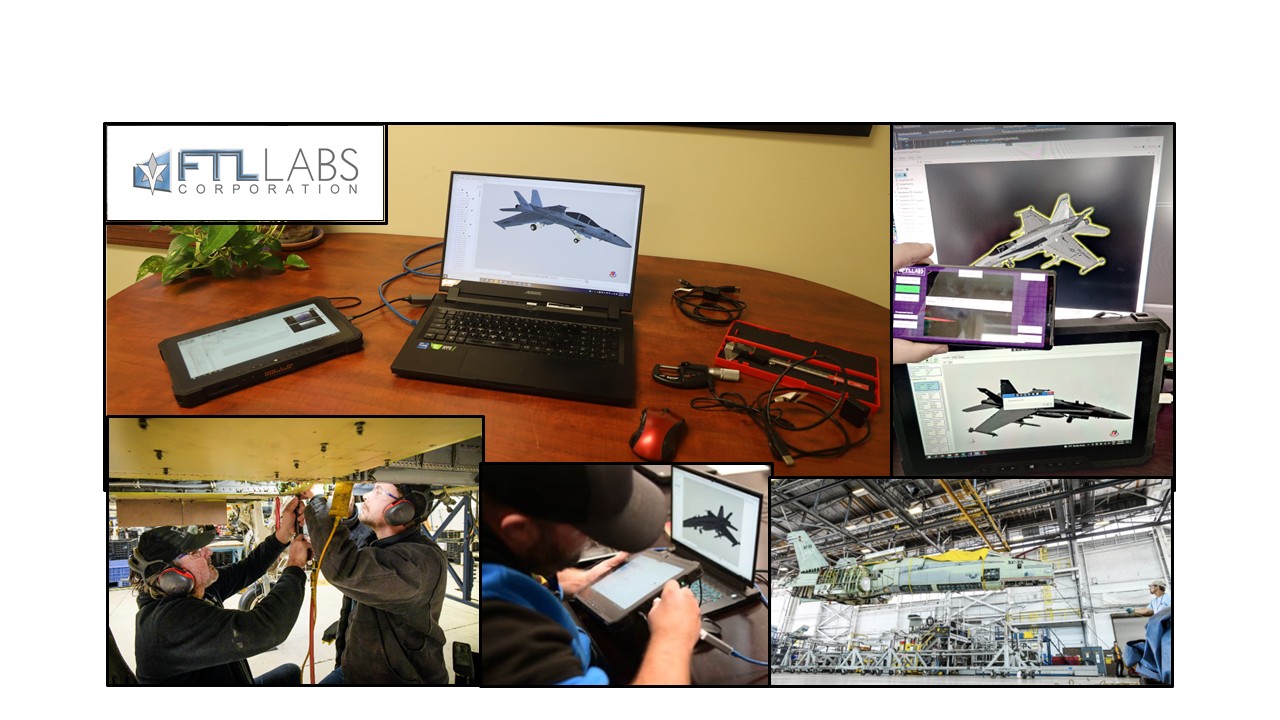

FTL Labs Corporation

Focus Area: Enhanced Inspection

Contact

Corey Countryman

corey.j.countryman.civ@us.navy.mil

360-315-7708

FTL Labs Corporation is a small engineering research and development firm in Amherst, Massachusetts. FTL was founded based on a team-building culture that enables us to solve complex multi-disciplinary problems in advanced technology areas with contributions of experts across the globe.

The people at FTL Labs are committed to pushing forward the cutting edge of technology. Working with ingenuity, integrity, and professionalism, we solve our customers’ most challenging problems in aerospace, manufacturing, big data, medical, AI, and robotics sectors.

Some of FTL’s capabilities include:

- Rapid Prototype Design and Engineering

- Optics, Imaging, and Sensing

- Fuels and Fluids Analysis

- Human Performance Optimization

- Biotechnology

- Big Data and Artificial Intelligence

- VR/AR and Advanced Interfaces

- Custom Software Solutions

The process of transforming enabling-technologies into profitable technology products requires orchestration of a variety of human resources including scientists, engineers, technicians, and business development professionals. FTL personnel have long experience with managing groups of interdisciplinary professionals and staying on-task, on-schedule, and on-budget.

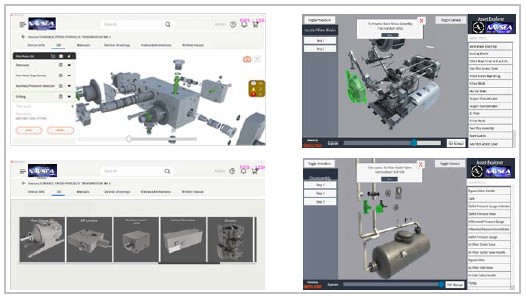

DADTMA (Distributed Acquisition Digital Twin Maintenance Architecture)

Problem Statement:

Traditional Maintenance, Repair, and Overhaul (MRO) practices in the DoD are struggling to adapt to increasing complexities in aircraft maintenance and quality assurance processes, including the use of digital tools and automated technologies to capture maintenance data and streamline workflow management. Current processes are inefficient, requiring time-intensive human-performed inspections and data collection before, during, and after maintenance tasks. The process frequently requires tedious and error-prone record keeping with pen and paper before transcription to a computer for access by teams.

Technology Solution Statement:

DADTMA is a software solution designed to collect, store, and analyze damage and repair data during naval depot maintenance and sustainment activities. DADTMA consists of a tablet app and a web app working in concert to rapidly collect data and store it in a Digital Twin in a secure GovCloud database. It employs automated USB tool data entry, 2D and 3D imaging, graphical database storage, data mining tools, and graphical data analysis to locate and track maintenance issues that are otherwise difficult to discern. It enables communication of that information across the Navy’s current software ecosystem. Ultimately DADTMA will provide a Naval Depot Maintenance and Sustainment tool that will increase the efficiency, repeatability, and accuracy of inspection results, for any asset type.

DADTMA integrates with USB tools used on depot shop floors and helps artisans organize that data by creating customized grids on 2D images of the work area. It then streamlines data sharing across sustainment roles by creating reports and integrating data to DADTMA’s web app. DADTMA’s website is accessible to anyone with the correct credentials, per our DoD customer’s defined roles. Finally, DADTMA’s Digital Twin provides predictive maintenance insights by comparing past maintenance events across a single or similar asset(s).

Benefits Statement:

Reducing costs and shortening maintenance turn-around times at aircraft depots is a high priority for the Navy. Responding to this need, DADTMA reduces manpower-intensive engineering costs associated with repair and maintenance inspections by accelerating data collection on depot floors and enabling the transfer of that data, along with asset and maintenance process information to the DADTMAnet Digital Twin. Primes such as Northrop Grumman anticipate a 10% time-reduction in inspections, yielding $10M in savings in lifecycle cost for a single product.

G.C. Laser Systems, Inc.

Focus Area: Coating and Corrosion Prevention

Contact

Magdalena Dajnowski

magdalena@gclasers.com

844-532-1064

G.C. Laser Systems Inc. is an American laser cleaning system manufacturer and a CWOSB with headquarters in Illinois. Our unique and globally patented laser cleaning technology is proudly designed and made in the USA. This proprietary technology was initially developed to clean cultural heritage buildings and artifacts with unmatched precision, and has evolved into many heavy duty industrial and DoD applications. From making our own scan heads and optics to fabricating our systems with durable stainless steel and powder coated aluminum to endure humid and corrosive environments, we specialize in delivering off the shelf and custom bespoke laser ablation tools that can work during all four seasons worldwide. Notable cultural heritage projects that have utilized our laser ablation technology include the US Supreme Court, the US Senate Building, Notre Dame, Sydney Harbor Bridge, Capitol of Maryland, the Egyptian Obelisk in Central Park, the Smithsonian, and buildings and monuments worldwide. On the industrial side our technology is used for rust removal, paint removal, chloride removal, surface prep, hydrocarbon removal, radiation decontamination, lead abatement, and various other industrial applications that demand precision and efficiency. Branches of the DOD such as the US Army, the US Coast Guard, and the US Air Force use our laser equipment to maintain and service valuable assets.

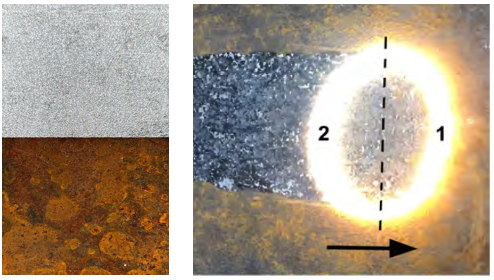

Laser Cleaning Technology

Problem Statement:

Removing corrosion and coatings from a variety of surfaces can be challenging and the process of abrasive corrosion removal can wear down the thickness of the assets being cleaned, reducing its useful service life, as well as pose environmental concerns with traditional blasting media and chemical stripping containment. Traditional cleaning techniques rely on consumables and have a lot of clean up and disposal costs.

Technology Solution Statement:

G.C. Laser Systems offers environmentally friendly, durable, and compact portable laser systems for removing rust, paint, coatings, and contamination from surfaces. Built with an in depth understanding of the photomechanical, photothermal, and photochemical effects that laser pulses can have on a surface, our highly tunable systems offer unmatched precision, control, and repeatability with laser ablation cleaning and surface prep. Corrosion, salts, and coatings are removed from metal surfaces without causing any damage or thickness loss to the substrate.Benefits Statement:

- Environmentally friendly.

- No consumables.

- No damage to substrate being cleaned.

- Less heat on surface than other laser ablation systems.

- Patented high speed and hot-spot-free laser cleaning.

- The beam never stops in one place and rotates at high RPM.

- 2-3 times faster cleaning than competitors.

- Designed and made in the USA.

- Made for use in humid and corrosive environments.

Google Public Sector

Google Public Sector brings the magic of Google to the mission of government and education. With powerful technologies such as artificial intelligence (AI), advanced analytics, and security offerings, decision makers can streamline processes and improve citizen services delivered by public sector organizations across all domains.

Focus Area: Business IT and Analytics

Contact

Shawn Mayo-Pike

518.322.7467

shawnjpike@google.com

Automating Shipyard Workflows with AI

Greensea IQ

Focus Area: Enhanced Inspection

Contact

Rob Howard

rhoward@greenseaiq.com

561-523-9210

Greensea IQ is a dual-use technology company transitioning mature solutions developed for and by the defense industry to the commercial markets.

With the competitive advantage of a 20 year head start Greensea IQ’s core technology OPENSEA is the open architecture operating software driving it all. OPENSEA is deployed on thousands of systems throughout the world’s oceans in both commercial and defense applications demonstrating the leadership we have in the development of advanced underwater robotics.

Through this trusted core technology we can now deliver advanced capabilities by combining edge-based solutions of navigation, autonomy, perception and AI with the cloud-based solutions of data, analytics, and intelligence into integrated robotic systems and services that allow us to extend our reach into the world’s oceans so that our work there may be persistent, efficient, and safe for our users and their assets.

EverClean is a great example of our ability to deliver a intelligent solution that can finally address a major issue facing all ship operators, the management of biofouling that accumulates on the hulls of ships.

As the only ready to deploy hull inspection and grooming solution that has been developed specifically to address the unique needs of the US Navy surface and submarine fleets, EverClean accomplishes this by providing efficient underwater hull maintenance at scale increasing fleet readiness and delivering maximum operational capabilities of the vessels.EverClean robotic underwater hull maintenance and inspection

Problem Statement:

Traditional in water hull cleaning and biofouling management methods are expensive, toxic, and ineffective. Proactive cleaning, the light brushing of ship hulls regularly, is proven to prevent biofouling from growing, providing a constantly clean hull unlike the traditional diver reliant service models and existing robotic capture solutions which are not viable or economically scalable for regular proactive service.

Technology Solution Statement:

The EverClean robot can deliver immediate, measurable impact through enhanced operational efficiency, superior performance, and reduced environmental footprint.

Its proven inspection capabilities enable more frequent and detailed assessments of hull condition, including corrosion, paint degradation, and physical damage.

EverClean is ready to scale to a one-to-one ship-to-robot model, enabling safe hull maintenance and inspection wherever the vessel is located– without relying on diver availability. In total, these capabilities translate into increased fleet readiness, reduced acoustic signature, and sustained performance.

Benefits Statement:

Greensea IQ uses advanced robotics as the enabling factor to offer vessel operators a revolutionary way to manage their fleet's hull performance. By maintaining a always clean hull we change the entire dynamic around hull maintenance from an inefficient, episodic or reactionary model, to a always clean intelligence-based model, further enhancing operational efficiencies through the constant collection and reporting of important ship hull data.

Hexagon Manufacturing Intelligence – Metrology Software

Focus Area: Enhanced Inspection

Contact

Cody Anderson

colton.anderson@hexagon.com

+1 (253) 349-1644

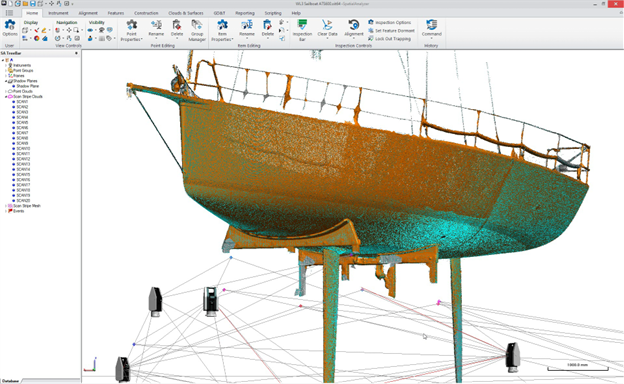

Hexagon Manufacturing Intelligence is the largest software developer in the metrology industry and offers a wide range of in-house developed, individually customizable software packages that deliver intelligent and effective data acquisition, analysis and evaluation as well as powerful data management and reporting tools. These solutions include: SpatialAnalyzer, Inspire, Geomagic, PC-DMIS, QUINDOS, BendingStudio, and more.

SpatialAnalyzer & Geomagic Design X Software

Problem Statement:

Shipyards face increasing pressure to modernize and maintain complex vessels and infrastructure while working with aging designs, incomplete documentation, and tight production schedules. Large-scale structures, limited accessibility, and constant configuration changes make it difficult to accurately measure, inspect, and align components. Disconnected measurement and design workflows slow repairs and overhauls, increase rework risk, and make it challenging to reliably reproduce or modify legacy parts and systems.

Technology Solution Statement:

Hexagon enables shipyards to connect physical reality to digital design using SpatialAnalyzer and Geomagic Design X.

- SpatialAnalyzer consolidates 3D measurement data from laser trackers, scanners, photogrammetry, and other portable metrology systems to deliver real-time insight into hull sections, foundations, machinery alignment, pipefitting and structural assemblies.

- Geomagic Design X converts scan and measurement data into precise, editable CAD models, allowing shipyards to reverse-engineer legacy components, validate as-built conditions, and rapidly design replacement or modified parts without relying on outdated drawings.

Together, these solutions establish a digital thread between measurement, inspection, and engineering across ship construction, maintenance, repair, and overhaul operations.

Benefits Statement:

With SpatialAnalyzer and Geomagic Design X, shipyards reduce rework, shorten maintenance and overhaul timelines, and improve confidence in fit, alignment, and installation. Teams gain accurate as-built documentation, faster part reproduction, and improved collaboration between quality, engineering, and production. The result is higher vessel availability, lower program risk, improved schedule predictability, and a scalable foundation for digital shipyard and modernization initiatives.

Hexagon Manufacturing Intelligence, Inc.

Focus Area: Enhanced Inspection

Contact

Jeff Elmer

jeffrey.elmer@hexagon.com

732-832-6809

Hexagon is a global leader in digital reality solutions, combining sensor, software and autonomous technologies. We are putting data to work to boost efficiency, productivity, quality and safety across industrial, manufacturing, infrastructure, public sector, and mobility applications. Our technologies are shaping production and people-related ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future. Hexagon’s Manufacturing Intelligence division provides solutions that use data from design and engineering, production and metrology to make manufacturing smarter. For more information, visit hexagon.com/mi.

Hexagon – Portable Scanning, probing, NDT/NDI, and much more.

Problem Statement:

Technicians face the challenge of requiring multiple devices to perform a variety of quality assessments, from non-destructive testing (NDT) to laser scanning and probing. This complicates the workflow, and escalates costs and training requirements. The need is for a singular, versatile system that can seamlessly transition between NDT, high-resolution laser scanning, and precise probing without sacrificing accuracy, efficiency, or functionality.

Technology Solution Statement:

A multifunctional tool like Hexagon's Absolute Arm could resolve multi-tool complexities by consolidating quality assessment needs into one integrated solution, thereby optimizing the quality control process. A 3D scan with the Absolute Scanner can be used on small to large objects with Hexagon’s AS1 and AS1-XL made for the Absolute Arm.

Benefits Statement:

- High accuracy measurements, with continual support.

- NDT Sensor

- For most Metals

- Capable to resolve volumetric flaws of 0.5mm and smaller

- Compliant with most codes: ASTM, ASME, etc…

- For most Welds

- Capable of resolving through-wall extensions of 5-10%T

- Compliant with most codes: ASTM, ASME, AWS, EN/ISO, API

- For most Composites

- CFRP / GFRP

- Easy to resolve 2.5mm flaws (and smaller)

- AS1 / AS1-XL Absolute Laser Scanner

- Complete digitizing from small to very large parts

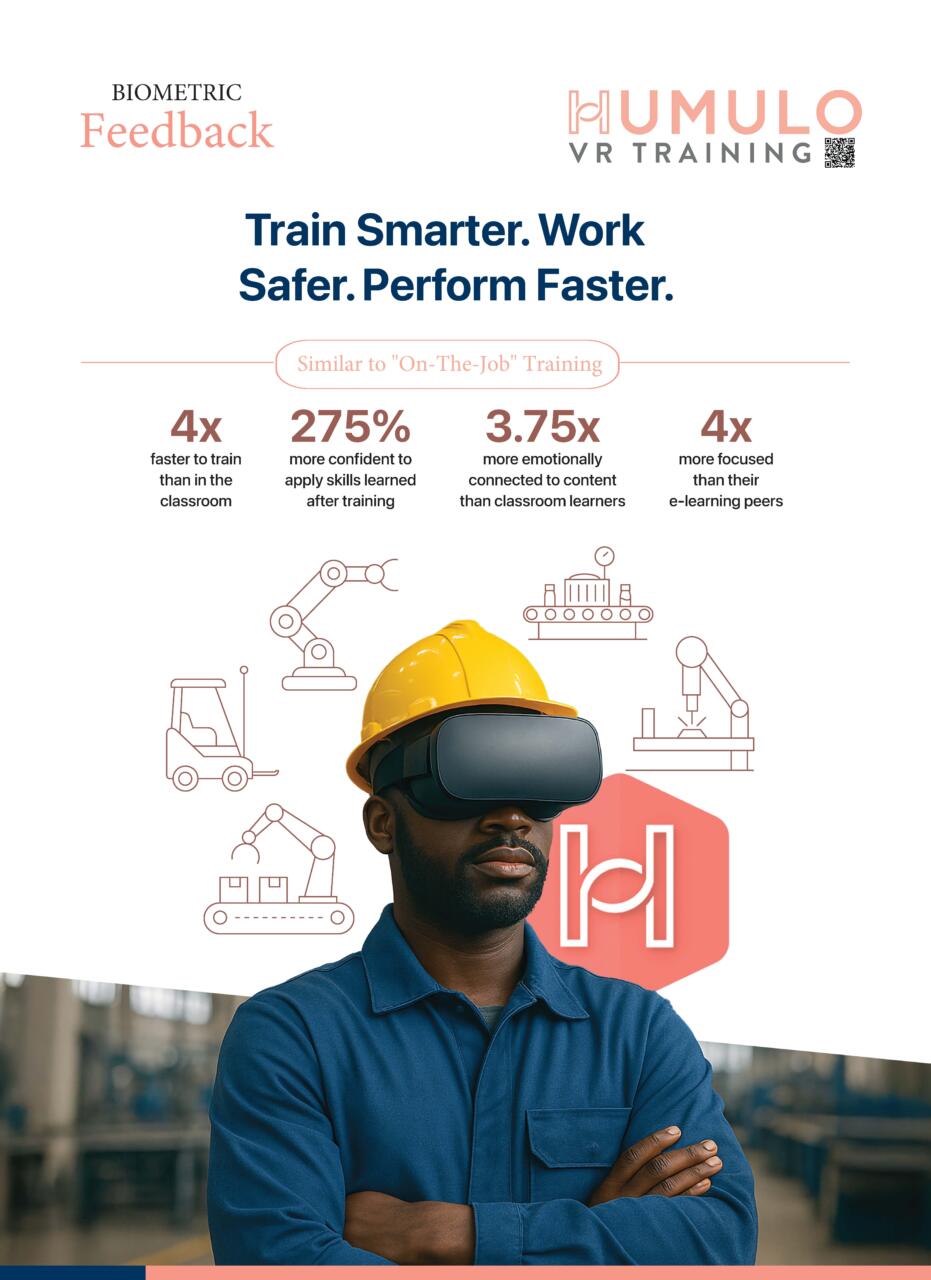

Humulo Engineering, LLC

Focus Area: Workforce Development/Visualization

Contact

Scott MacAdams

Scott.macadams@humulo.com

443-295-3706

Humulo Virtual Reality Inc. delivers immersive, procedure-accurate safety and maintenance training for industrial and government environments. Our headset-based platform turns existing SOPs, TTPs, and job sheets into interactive simulations covering lockout/tagout, hot work, confined space, fall protection, rigging, forklift/crane basics, electrical PPE, and hazard recognition. Trainees practice full workflows—identify hazards, don PPE, verify isolation/atmosphere, execute steps, complete QA—while the system captures objective performance data (timing, errors, decision paths) in xAPI for LMS/LRS integration and after-action review.

Designed for field constraints, HumuloVR runs offline on portable headsets (PICO or similar), sets up in minutes, and supports multi-headset sessions without special rooms or network dependencies. Content comes from our Full Library plus rapid custom modules built from customer materials (docs, videos, CAD/drawings). Deployment is turnkey: imaged headsets, carry cases, casting to TVs for group observation, and role-based access controls.

We host in U.S.-based AWS with SOC 2 Type 1 controls and data minimization, and support customer-managed deployments when required. Primary customers include shipyards, energy and manufacturing sites, logistics operations, and government programs needing safer, faster qualification at scale—without consuming scarce equipment or pier/yard capacity. Our focus is practical impact: reduce incidents and rework, accelerate time-to-competence, and standardize best practices across shifts and shops.

Maintenance Virtual Simulation Training

Problem Statement:

- High-consequence tasks with limited safe hands-on practice

- Inconsistent procedure execution across shifts/shops

- Instructors/time constrained; hard to scale training throughput

- Rare casualty states and error paths are difficult to replicate

- Limited, non-objective proficiency data for authorizing work

Technology Solution Statement:

- 3–4× faster time-to-competence vs. classroom walk-throughs

- Fewer errors/rework through realistic, repeatable reps of high-risk tasks

- Standardized procedures across teams with objective proficiency evidence

- Higher instructor leverage via automated scoring and AARs

- Portable, on-base training without tying up equipment or pier time

Benefits Statement:

- Converts SOPs/TTPs into interactive VR simulations with guided steps and fault injects

- Runs offline on portable headsets; syncs for analytics when connected

- Auto-scores actions, timing, and errors; exports xAPI to existing LMS/LRS

- Rapidly builds custom modules from customer materials; updates in days, not months

HYTORC

Focus Area: Reliability Improvement (Hardware)

Contact

Michael Shannon

mshannon@hytorc.com

201-512-9500

HYTORC is the most trusted name in the industry. HYTORC makes industrial bolting safer and simpler. With 50 years of experience focused entirely on developing the highest quality industrial bolting systems and tools, from steel mills and mining equipment to refineries, power plants, and wind turbines; we have developed solutions for every bolting application imaginable. For custom projects, our highly experienced engineering team is at your service to design the most efficient solution for your job with simple, safe, and economical pricing in mind. We are consistently improving upon existing products, and developing new tools, based on feedback from the people that use our tools every day. Our latest product line features patented industry-firsts like hands-free operation to keep tool operators at a safe distance from the application, onboard documentation systems to provide job accountability and assurance, and industry-leading bolt load accuracy to reduce nut loosening and joint failure.

Industrial Bolting Specialists

Problem Statement:

Many companies have Bolting Issues:

- Torquing, Tightening, Specifications to be met.

- Incorrectly tightening or torquing bolts can cause fingers to be severed.

- Over-Torquing bolts can cause substrates to weaken and crack

- Under-Torquing allows bolts to come loose and wreak havoc

- Incorrect maintenance procedures lead to equipment loss,

- Loss of time and manpower.

Technology Solution Statement:

HYTORC Bolting Solutions

- Correct tools for job

- Correct maintenance and calibrations schedules

- Increased Safety

- Training for users

Benefits Statement:

Creating a safer bolting and torquing environment for end users while reporting maintenance to management.

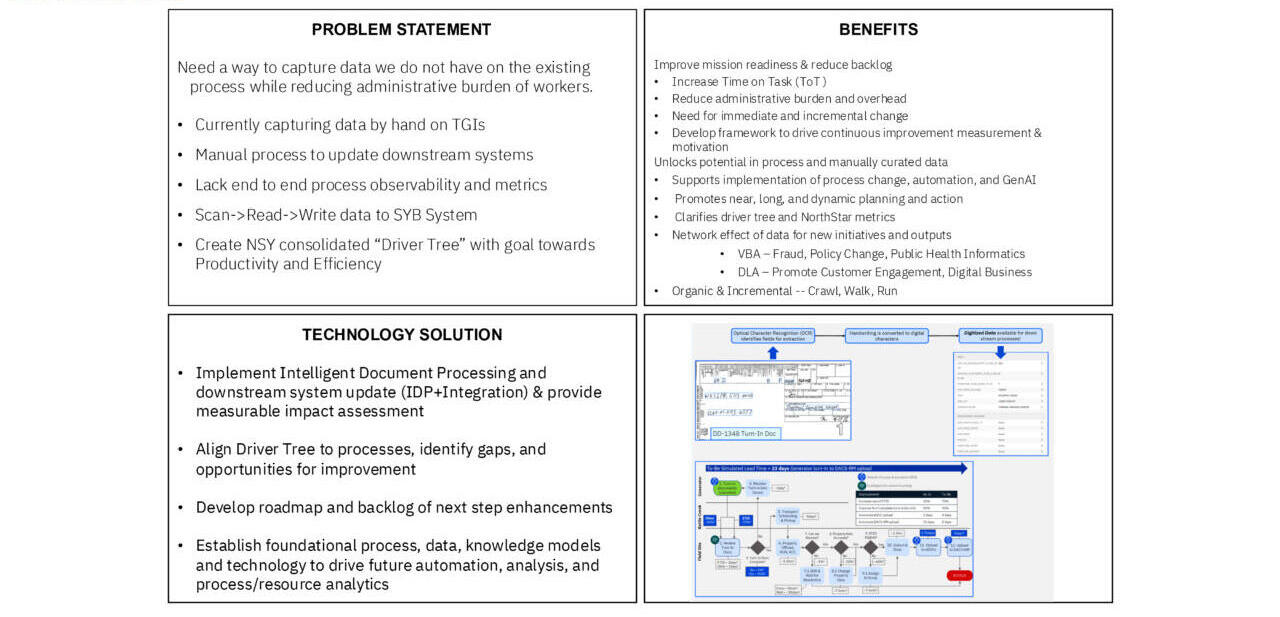

IBM Consulting

Achieving full mission readiness is becoming increasingly complex and requires dynamic defense technology solutions. New threats and domains for warfare continually emerge, including cyber and space along with disruptive technologies, like AI and Quantum. Dealing with these threats necessitates using data as a critical enabler for information driven operations.

As defense departments navigate increasingly sophisticated threat landscapes, they are eyeing a shift to a DevSecOps mindset to ensure they can securely innovate. At a recent roundtable, produced by Government Executive Media Group and hosted by IBM and Red Hat®, DoD experts provided insights on the critical role that DevSecOps plays to support the mission. These insights are captured in the Top Takeaways: 4 Ways the Defense Department Can Leverage DevSecOps and a report from the IBM Center for the Business of Government on Achieving Mission Outcomes through DevSecOps.IBM can help you transition to an advanced hybrid cloud-based environment built on technology that is designed for your mission, including AI, SAP S/4HANA and “cloud to the edge” innovation. Through the IBM cloud management capabilities including Red Hat OpenShift®, you can securely access data anywhere within this new environment, regardless of cloud provider—or even if the information resides on in-house systems.

Focus Area: Business IT and Analytics

Contact

Brian Sean FitzPatrick

Brian.Sean.FitzPatrick@ibm.com

619-213-7263

Shipyard Digital Transformation – TGI Reader

Impacto Protective Products

As a leader in the personal protective product industry Impacto Protective Products provides customers with innovative products that enhance safety and productivity in the workplace. Our network of sales staff works closely with customers across a wide range of industries to produce measurable results.

We have long been recognized for products that protect against workplace injuries by assuring exceptional levels of protection. We specialize in design, manufacturing and distribution of custom ergonomic products to help prevent a wide range of cumulative trauma and repetitive strain injuries.

Impacto® products are distributed around the world and are used in many job applications including manufacturing, warehousing, assembly lines, industrial applications, construction, mining industry, forestry, office settings and many more.

With over 25 years in the industry IMPACTO® is highly regarded as a premium, manufacturer of ergonomic and safety products. We pride ourselves in attention to detail, superior product quality and customer service. We are committed to customer satisfaction, continual improvement of our products, expanding our markets by developing specialized personal protective equipment and compliance with ISO 9001:2008 quality system. For full details, please visit our website www.impacto.ca.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Ergonomic PPE

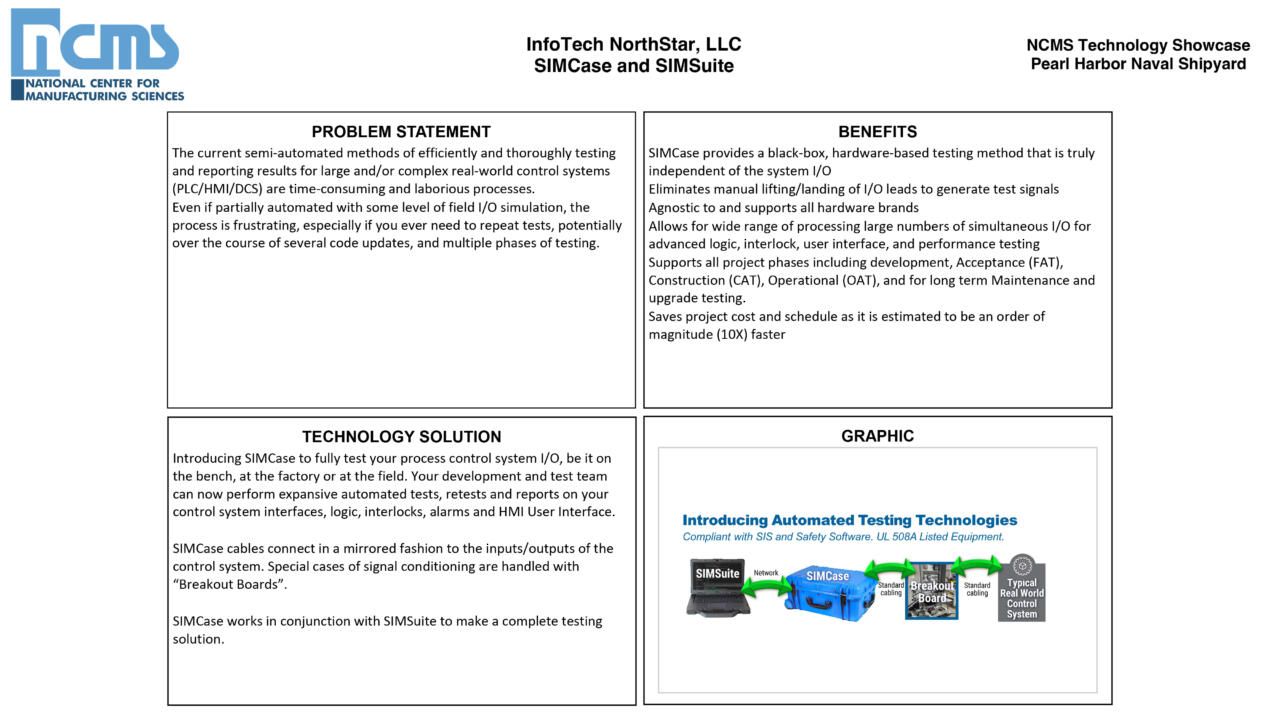

InfoTech NorthStar, LLC

InfoTech NorthStar, LLC (ITNS) provides professional, technical and engineering support services in several related fields for all phases and types of project, task and service-based work. When we started ITNS, we saw a need in the Government Sector to offer these types of wide-ranging services. ITNS is based in Richland, Washington, and supports the community by hiring many of our employees locally. ITNS is a small, disadvantaged, woman-owned business that while local first, is expanding its reach throughout the entire Government Sector with its task and professional, technical and engineering support services focused offerings. ITNS, LLC was formed and is registered in Washington State in October of 2021 as a consortium of local, experienced Government contractors with over 50 years of combined experience at Government sites around the country. ITNS, LLC is registered with the Washington Secretary of State, Corporation Commissioner and maintains licensed Professional Engineers (P.E.) and other credentialed personnel in many fields on its team.

Focus Area: Enhanced Inspection

Contact

Nolan Wright

nolan.wright@infotechnorthstar.com

509-531-8890

SIMCase and SIMSuite

M.S.M. Industries, LLC

Focus Area: Advanced/Additive Manufacturing

Contact

Darryl Clare

Darryl.Clare@msm-ind.com

209-479-2753We deliver specialized materials and components that enable platforms to perform faster, cooler, and quieter. From design through scalable production and reusability, we integrate solutions that adapt and evolve with our customers’ most pressing challenges. We're a seamless extension of our partners — driving innovation, reliability, and mission success together. Our mission is to engineer materials and solutions for exceptional performance — owning the full value chain from concept to sustainment, delivering unmatched capabilities in the world’s most demanding environments.

Advanced signature and thermal management materials

Problem Statement:

Need for high-performance materials that can operate at elevated temperatures and provide signature management in all areas of the physical spectrum.

Technology Solution Statement:

MSM delivers highly specialized materials and components with exceptional thermal protection, absorption, and signal reduction characteristics. These technologies enable platforms to move faster, cooler, and quieter – from the ocean’s depths, to the vast frontier of space.

Benefits Statement:

MSM focuses on signature reduction materials to solve system issues such as radar cross-section (RCS), antenna isolation, thermal control, sonar detection and vibration damping performance.

Metronor

Focus Area: Enhanced Inspection

Contact

Mariano Marks

mariano.marks@metronor.com

248-345-6157

Metronor is an ISO 9001 certified high technology company with offices in the USA, Norway, and Germany. With over 30 years of expertise in portable metrology, our technology empowers users to measure, align, and scan large-scale assemblies from aerospace structures to automotive tooling as well as industrial fixtures and tubes. Our systems provide high accuracy and precision without using any stickers, markers, or references. Our modular camera-based systems are robust, flexible, and easily upgraded and customized to meet evolving production demands.

Portable probing and portable laser scanning solutions

Problem Statement:

Pipes and tubes need to be replaced with an exact replica to ensure fitment. Traditional methods are slow and removing a pipe causes it to unflex making it harder to measure and ensure its replacement. The locations of pipes and tubes are often in inaccessible places further complicating obtaining a digital twin.

Furthermore, when pipes are bent, pipes of different materials and thicknesses will vary when trying to hone in the bending process. Inconsistencies in bending results in pipes that won’t fit which wastes time and materials.

Technology Solution Statement:

Metronor has devised a shipyard solution to specifically tackle this challenge.

Clamping a camera rather than using a standard tripod and using a shorter Lightpen for probing in more cramped environments ensure that pipes and flanges are measured and reverse engineered properly. The system case also includes a battery for environments where electricity isn't readily available.

Measure pipes of any size directly on tube benders and send corrections back to the tube bender.

Benefits Statement:

The Metronor system is an easy-to-use, sticker-free, industry proven solution that provides accurate and precise data both in the lab and the shop floor.

Our highly customized, portable solutions can adapt to applications from small to large-sized parts resulting in less line-of-sight issues when measuring due to the ability to use multiple cameras and long probe extensions.

Direct interfaces with metrology software means the raw data is provided for analysis and less time is taken transferring data over.

No moving parts also means no recalibration of the system as well as less downtime and long durability.

Moth+Flame

Focus Area: Workforce Development/Visualization

Contact

Matt Frost

matt@mothandflamevr.com

619-228-3395Readiness Through Immersive Training

Problem Statement:

Experience matters for the DoW. Currently a lack of experience for simple and complex skillsets is limiting factor. Additionally a lack of data to paint a clear picture of capability.

Technology Solution Statement:

Using immersive training war fighters can train anywhere they are in mass to create a baseline of measured experience.

Benefits Statement:

Create sets and reps without risk to make a more capable service member.

Relativity Space

Focus Area: Advanced/Additive Manufacturing

Contact

Joe Gerringer

jgerringer@relativityspace.com

713-409-3966

Relativity Space is building reusable rockets that make access to space more reliable and routine—empowering science, exploration, and innovation beyond our planet. Energized with new leadership and a bold mission, we’re launching forward with purpose and precision. Our core innovation doesn’t stop at rockets. From cutting-edge research labs and interplanetary exploration to next-generation manufacturing, we’re building platforms that push boundaries far beyond launch. We are revolutionizing how complex hardware is manufactured through our AI-enabled autonomous robotic platform, Stargate. By integrating large-scale additive manufacturing, advanced materials, robotics, and data-driven process control into our technology stack, we’re building a scalable and resilient industrial base for the future.

Sustainment Through Autonomous Robotic Repair (STARR)

Problem Statement:

The U.S. manufacturing industry is emerging from a decades-long decline and demands leap ahead technology solutions for the future. Relativity Space is leading the American reindustrialization effort by developing and deploying manufacturing technologies that replace traditional manufacturing supply chains while meeting stringent reliability standards. Our initial focus is addressing the urgent need for large-scale metal castings in the defense sectors.

Technology Solution Statement:

STARR seeks to expand additive manufacturing and casting repair processes beyond traditional weld cells by combining autonomous perception, cooperative robotics, path planning, and fleet modularity.

Through the creation of semi-autonomous repair robots, STARR is addressing casting capacity issues by reducing supply chain uncertainty and improving technician safety by decreasing human operations in mission critical casting repairs. The development of these systems will reduce operational costs for the Defense Industrial Base and increase fleet readiness.

Benefits Statement:

- Resilient Supply Chains: Flexible production that adapts quickly to industry needs.

- Unconstrained Build Volume: Maximum configurability for manufacturing massive component sizes.

- Full-Stack Capability: Combining automation, simulation, inspection, and more.

- Speed & Efficiency: Leveraging data science, robotics, and proprietary deposition technology to slash lead times.

- Mission-Critical Hardware: Reliability for high-performance applications and extreme environments.

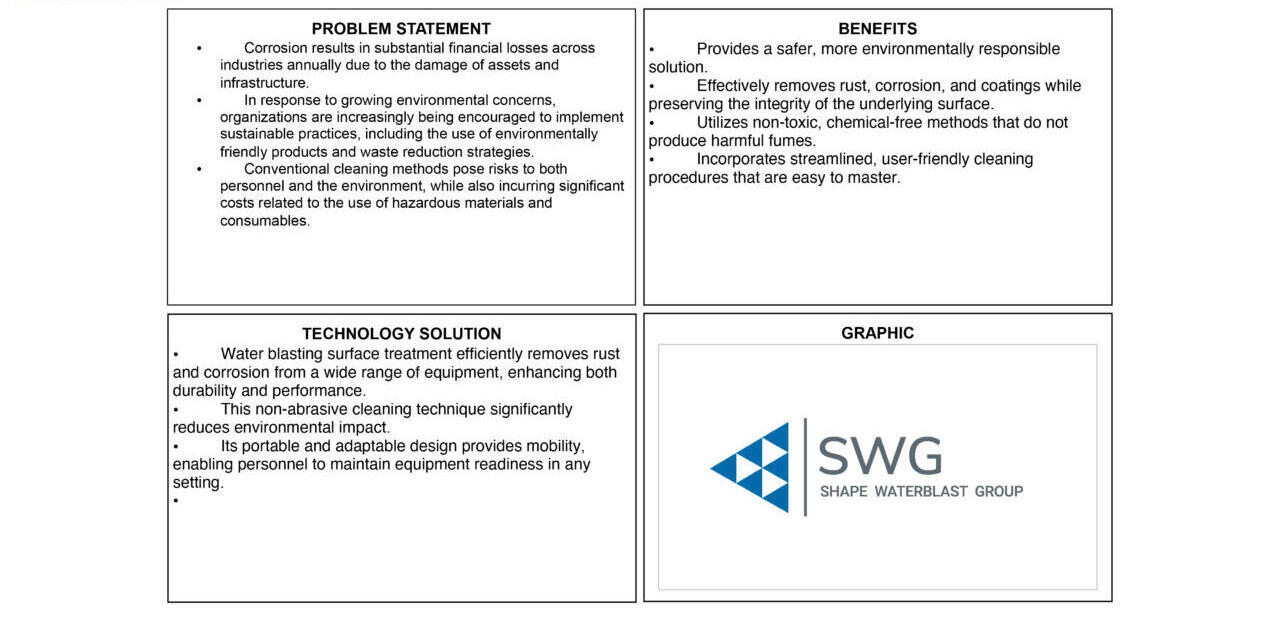

Shape Waterblast Group

The SWG (Shape Waterblast Group) combines premier waterblasting companies under the Shape Technologies Group, the global leader in ultrahigh-pressure technology solutions. Unifying APS, Aqua-Dyne, RPS, and Flow SP under a single umbrella empowers us to harness over 125 years of collective wealth of expertise, resources, and innovation. This enables us to provide an even more robust and comprehensive solution at an unparalleled value to our customer’s needs.

Focus Area: Coating and Corrosion Prevention

Contact

Chris Ewart

cewart@shapetechnologies.com

346–218–8265Ultra High Waterblasting Equipment

Siemens Government Technologies

Focus Area: Advanced/Additive Manufacturing

Contact

Robert Tye

robert.tye@siemensgovt.com

703-789-5409

Combining the real and the digital worlds makes it possible to seamlessly integrate the entire value chain from design to realization, while optimizing with a continuous flow of data. A true Digital Enterprise is able to harness the unlimited power of data by gaining valuable insights to make fast and confident decisions – and to create best-in-class products through efficient production.

Digital Simulation of Production

Problem Statement:

Aging infrastructure, inefficient layout and old equipment are contributing to longer maintenance times, increased costs and reduced fleet readiness.

Technology Solution Statement:

Provide a digital model to identify equipment and process solutions that increase throughput through experimentation, and further set the state for equipment procurements and facility designs that enable improved operations.Benefits Statement:

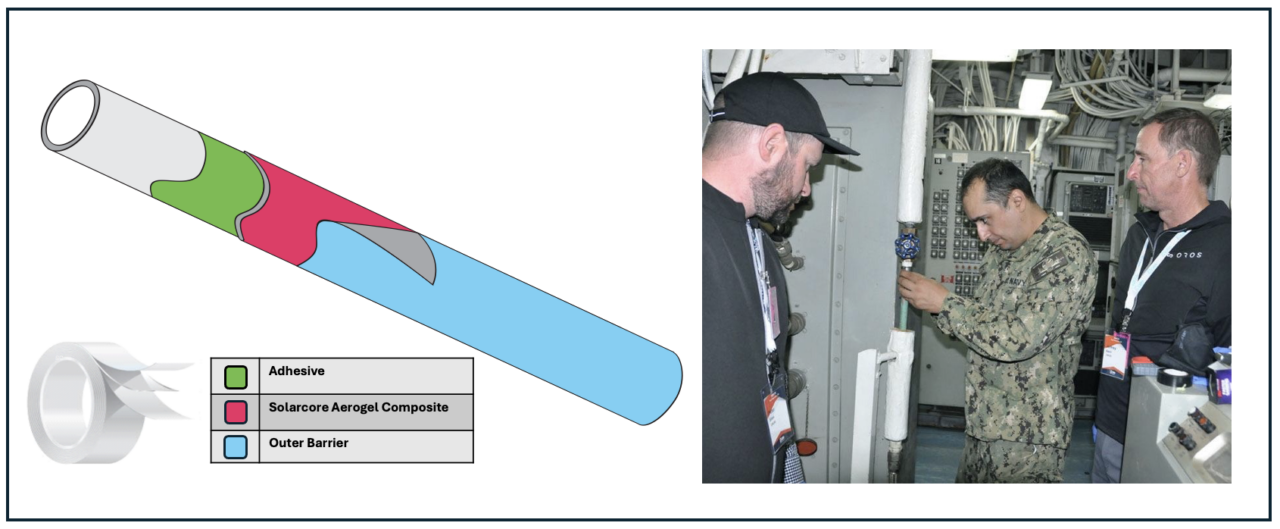

Digital model of the maintenance process: maximizes allocation of resources, provides framework for data driven optimization, maximizes workforce allocation, targets faster ROI for project investments.Solarcore

Focus Area: Coating and Corrosion Prevention

Contact

Jeff Nash

jeff@solarcore.tech

510-501-3060

Solarcore is a materials technology company that develops the most scientifically innovative thermal solutions on the planet. Solarcore is a dual-use company with material sales objectives in government and commercial sales. Its core competencies are technology development of thermal materials, market development of thermal solutions, and dedicated marketing and sales in consumer, commercial and government markets.

Solarcore specializes in developing and commercializing high efficiency thermal insulation based on aerogel composite materials. Aerogels are the lowest density, most thermally efficient materials on earth that are composited with common form factor materials including fibers, textiles and foams to supercharge the performance of commonly used substrates.

Solarcore is currently performing for four additional US Department of Defense contracts including shelters, apparel, cold weather boots, and medical supply logistics containers. It continues to develop and sell thermal solutions for commercial and consumer markets.

Aerogel composite foams, sold as Solarcore®Foam, have been commercialized and in the market for over 5 years. It is currently adopted in insulated footwear from brands such as Merrell, LL Bean, Cabelas, OROS Apparel and others. This first-generation technology is a closed cell foam boosted with silica-aerogels for superior thermal performance over all other foam and high loft insulations. This product is available in a standard and breathable form for different market applications and sold in sheets from 2mm to 10mm.

Ultra-Thin Heat Shield Using Polymer-Aerogel Insulation to Reduce Heat Transfer and Thermal Signature of Extreme Temperature Sources

Problem Statement:

A common problem associated with traditional chill water pipe lagging is corrosion under insulation (CUI). When chill water runs through piping on ships condensation builds up and drips on pipes as well as fittings and other components in the vicinity. This causes:

- Costly corrosion to equipment, fittings, other components

- Requires down time for repairs and replacement

- Inefficient insulation impacts chill system performance

- Comfort and habitability problems for the environment

Technology Solution Statement:

Solarcore’s proprietary polyimide lagging alternative offers an easy to install solution which is fast and effective. The low-profile aerogel material eliminates thermal transfer with only a few millimeters of thickness attached directly to surface of the piping, elevating the surface temperature above the dew point away from the pipe eliminating condensation formation in critical areas. This is accomplished by taking advantage of the patented nano-porous non-shedding polymer aerogels and providing properties to minimize conductive and convective heat transfer.

Benefits Statement:

Current chill water pipe lagging is bulky and takes up valuable space on ships as well as a cumbersome installation process. Solarcore’s polyimide aerogel thermal management materials provide:

- Improved thermal efficiency which equates to less use of energy to maintain proper temperatures

- Space savings from a thinner more efficient solution

- Easily installed products in the event of needed repairs

- Characterization data for the aerogel material data shows performance gains with a much lower profile than existing products

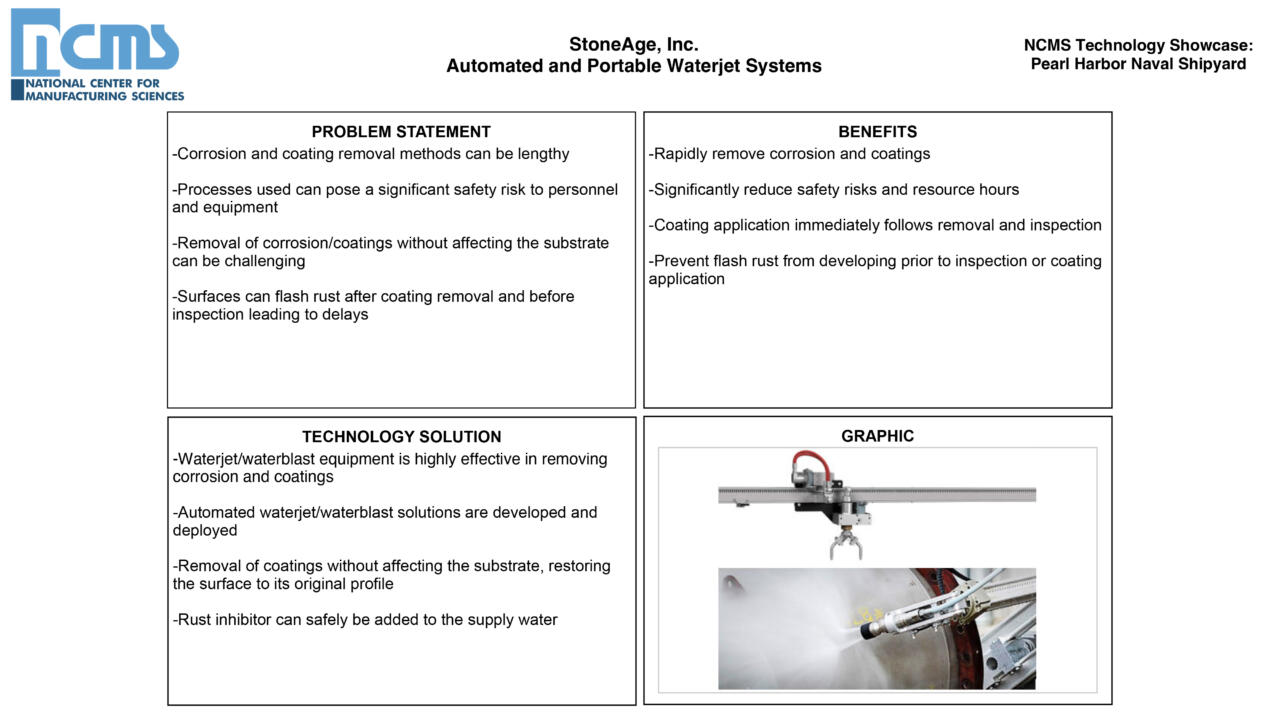

StoneAge, Inc.

StoneAge is an engineering and manufacturing center for high pressure waterblast tools used for industrial cleaning. Our primary focus is to introduce fully automated tooling to remove operators from the dangers of high-pressure water. StoneAge recently acquired Terydon who specializes in heat exchangers and condensers.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Michael Gonzales

303.204.6127

michael.gonzales@stoneagetools.com

www.stoneagetools.com

Automated and Portable Waterjet System

TRI Austin

Focus Area: Enhanced Inspection

Contact

Mark Keiser

mkeiser@tri-austin.com

316-519-1966

TRI Austin is a leading research and development organization specializing in advanced materials, nondestructive testing (NDT), and innovative engineering solutions. With a strong focus on cutting-edge technologies, TRI Austin serves industries such as defense, aerospace, energy, and manufacturing, delivering tailored solutions to meet complex technical challenges.

Our multidisciplinary team of mechanical, electrical, and computer science engineers, and software developers collaborates to design, prototype, and implement state-of-the-art systems that enhance operational efficiency, reliability, and safety. TRI Austin is renowned for its expertise in robotics, ultrasonic scanning, automated inspection systems, materials characterization, and leveraging these capabilities to drive innovation in critical applications.

As a trusted partner to government agencies and private sector clients, TRI Austin is committed to advancing the frontiers of technology through rigorous research, precision engineering, and a dedication to quality. Our mission is to provide transformative solutions that empower our clients to achieve their goals while maintaining the highest standards of performance and integrity.

Cobots for NDI

Problem Statement:

Inspections are difficult and that difficulty is increase by human factors. Those factors can be keeping track of 1200 fasteners on a wing being inspected or holding an inspection unit over you head to inspect those 1200 fasteners. While inspectors are holding the scanner over their head in a particular spot they also have to watch the inspection unit to verify that data is good and identify any defects.

Technology Solution Statement:

TRI Austin will leverage previous experience in developing non-destructive inspection methodologies and integrating them with collaborative robots to demonstrate this capability on aircraft. The technology areas of interest defined by the USN include:

- Advanced Robotic Systems Integration for Aircraft Maintenance and Repair

- Human-Robot Collaboration and Safety in Aviation MRO

- Emerging Technologies for Autonomous Aviation Maintenance

TRI has developed a demonstrator collaborative robot (cobot) that optimizes workflow efficiency and further develops Human-Robot Collaboration for use in overhaul maintenance and repair of aircraft.

Benefits Statement:

- Utilizing cobots will decrease inspector stress by eliminating manual probe holding and awkward arm positioning during scanning.

- Inspection quality will improve with automated data collection and saving, allowing the inspector to focus entirely on data quality

- Cobots allow documentation of inspection sites to verify 100% inspection has been achieved

- Preliminary demonstrations have indicated a 20% decrease in inspection time

- Cobots allow for significantly improved accuracy during inspections as compared to inspections done by hand

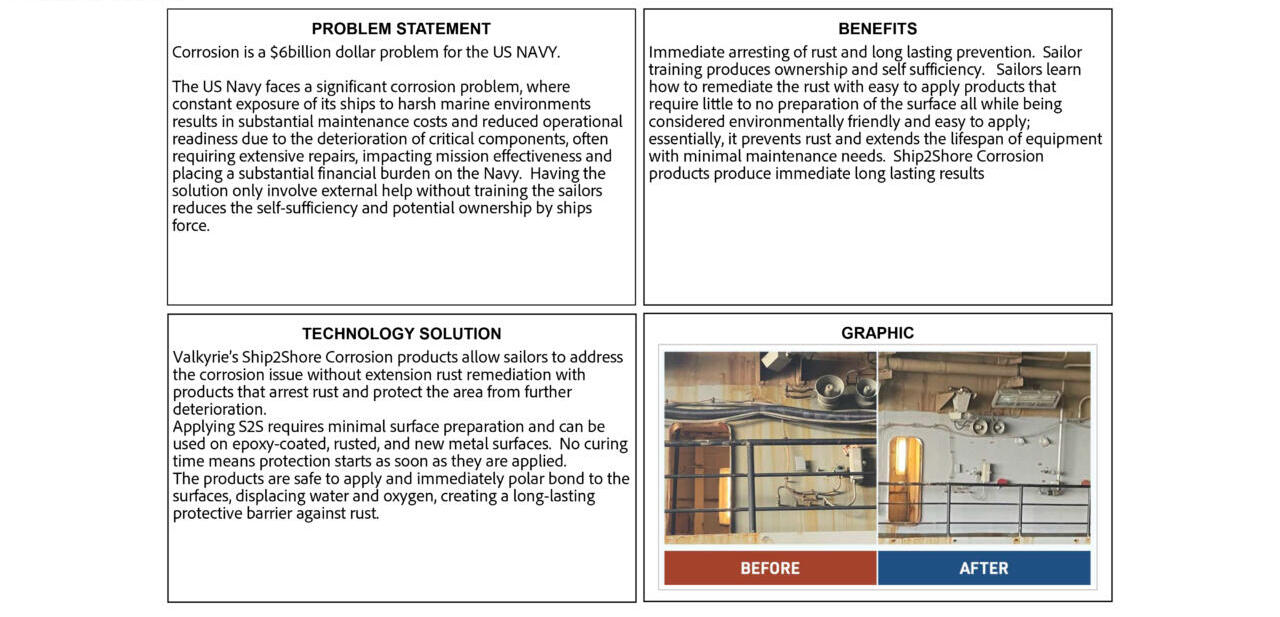

Valkyrie Enterprises

Valkyrie Enterprises enhances defense and industrial operations by providing engineering and technological expertise, real-world and simulated training programs, critical infrastructure security and products, data analysis in virtual environments, systems engineering and training analysis, and hands-on maintenance and fabrication services.

Valkyrie Enterprises is an innovation-focused company that elevates customer goals from baseline to astounding.

Focus Area: Coating and Corrosion Prevention

Contact

Jason DeHart

jason.dehart@valkyrie.com

716–796–3044

Ship 2 Shore Corrosion Control

VRC Metal Systems

Focus Area: Advanced/Additive Manufacturing

Contact

Gentry Boswell

gentry.boswell@vrcmetalsystems.com

605-431-4144

VRC Metal Systems, LLC is a company founded in 2013 based on research performed at South Dakota School of Mines and Technology in collaboration with the US Army Research Laboratory (ARL) to design a hand-operable high-pressure cold spray capability. The goal of advancing this technology was to allow for simple but high-quality repairs of DOD assets either in a depot or field environment. Since its founding, VRC Metal Systems has continued to develop this technology, creating more highly portable systems as well as producing robust systems for continuous commercial operation. VRC has successfully commercialized a line of high-pressure cold spray capabilities that has successfully enabled new production and repair activities in the DoD, the energy sector, the heavy industrial sector, and in research and academia. VRC is also working with ARL and other DOD entities to advance the state of the art in High Deposition Rate Additive Manufacturing (HD-RAM) processes like cold spray additive manufacturing, wire directed energy deposition, friction stir additive manufacturing, as well as developing secondary processing techniques for these processes like localized thermal processing, secondary deformation processing, or even machining. VRC is a full service cold spray provider, core capabilities include: Cold Spray Process Development; Equipment Manufacturing, Integration & Leasing; On-Site Repair and Modification; Consumables; Training and Customer Support.

Cold Spray Solutions for Corrosion and Wear

Problem Statement:

Corrosion and Wear on High Dollar, Long Lead Time Parts and Components