NCMS is committed to building a strong, resilient manufacturing sector and industrial supply chain by accelerating the development, demonstration, adaption, and adoption of innovative technology. Through public/private collaborations with federal and state government, industry, and academia, NCMS catalyzes advanced technology solutions that deliver new capabilities to solve the toughest challenges. Over the past four decades, NCMS has been instrumental in accelerating the development and transition of countless cutting-edge solutions. As NCMS grows and evolves, here are the primary technologies from which NCMS partners have sought solutions for expanding productivity, efficiency, and value.

Additive Manufacturing | Artificial Intelligence | Biotechnology | Business Process Management | Coatings/Corrosion Prevention | Communications/Data Transmission | CBM+ and Predictive Maintenance | Digital Engineering | Energetics | Energy | Environment, Health, and Safety | Enhanced Inspection/Metrology | Hardware | Hypersonics | Materials Science | Quantum Technology | Robotics, Mobility, & Automation | Software and Data Analytics | Space Technologies | Workforce Development and Training

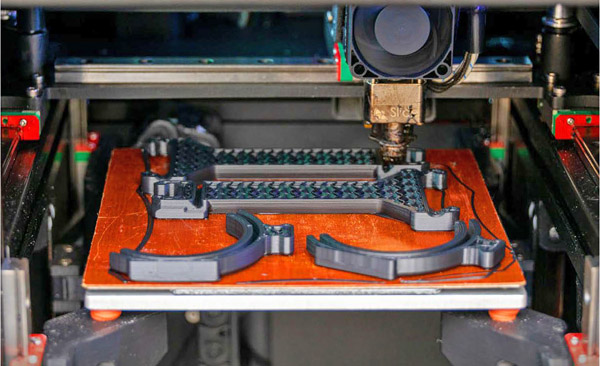

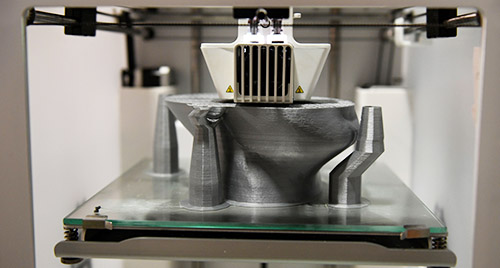

Additive Manufacturing

Additive manufacturing (AM) is the process of depositing thin layers of materials using digital 3D model data to produce an object of virtually any shape. AM is versatile, flexible, and highly customizable, utilizing a variety of materials including polymers, metals, ceramics, composites, and biomaterials. AM applications continue to grow as new processes are advanced—everything from binder jetting, to powder bed fusion, to vat photopolymerization and more, enabling AM to support a wide range of industries.

AM allows manufacturers to not only conduct rapid, cost-effective prototyping for R&D processes, but also to produce scalable, customized, just-in-time parts with less material and waste. AM also innovates with cutting-edge advanced materials to deliver more durable, lighter weight components for multiple industries including automotive, aerospace, defense, and medical.

For those who desire AM capabilities to furnish replacement parts while in remote locations, advances in data transmission such as "distributed and disconnected advanced manufacturing" now enable a needed part's engineering data to be securely accessed in a format usable by a 3D printer.

Artificial Intelligence

Artificial intelligence (AI) comprises the capacity of machines and computer systems to perform tasks that normally require human intelligence. It uses algorithms and large datasets to recognize patterns, make predictions, generate written and visual content, and automate processes without direct human input, allowing machines to act or "think" in human-like ways to accomplish specific goals. AI in the manufacturing sector has more specific applications: software systems are designed to recognize, simulate, predict, and optimize situations and processes, operating conditions, and material properties for human and machine action. As a subset of AI, machine learning (ML) refers to algorithms that use prior data to accurately identify current state and predict future state with the goals of improving productivity, precision, and performance.

AI and ML are essential to the continued advancement of smart manufacturing, which enables manufacturers to extract significantly increased value from their existing assets and data resources, at network scale, using digitalization. Benefits of AI include more streamlined operations, enhanced productivity, better-informed decision-making, improved demand forecasting, and reduced costs.

Business Process/Management

Business process management (BPM) is a discipline that uses various methods to discover, model, analyze, measure, improve, and optimize business strategies and processes. The use of BPM synchronizes people, systems, and information to streamline operational efficiency, enhance productivity, and drive innovation by aligning organizational processes and fostering a culture of continuous improvement.

In the manufacturing sector and many other organizations, business process management methods ensure that companies include all relevant stakeholders, define business procedures, create a single source of truth, support strategic initiatives, share information quickly, collaborate for continuous improvement, and facilitate automation.

Related Stories:

Coatings/Corrosion Prevention

Corrosion—the naturally-occurring deterioration of a material, usually a metal, due to chemical reactions with the environment—is an insidious problem across the globe. Impacting every aspect of our daily lives, corrosion weakens the steel and concrete used to support our roads, tunnels, and drinking water systems. Nearly every sector of the economy is impacted by corrosion, especially infrastructure, transportation, manufacturing, energy, utilities, and defense. Corrosion costs the global economy over $2.5 trillion annually.

For decades, NCMS has convened technology demonstrations to advance corrosion assessment and monitoring systems, corrosion inhibitors, and corrosion-protective coatings such as thermal spray coatings, micro arc oxidation, polymeric coatings, and more.

Communications/Data Transmission

Advancements in communications and data transmission technologies continue to fuel growth in every sector of the economy. While the harnessing of radio waves to transmit voice and text data ushered in the widespread use of cell phones, later advancements contributed to the rise of wireless networks enabling smart phones, WiFi, and more. Each new advancement in wireless data transmission has spurred new products and services. For instance, 5G networks have brought much faster download and upload speeds, enabling edge computing, cloud computing, AI, smart factories, smart cities, AR/VR, and autonomous vehicles. Mesh networks, which use autonomous wireless nodes to communicate with peer nodes, are ideal for connecting IoT devices and sensors in many contexts including manufacturing, defense, oil and gas, mining, and warehouses. Meanwhile, fiber optics continue to progress in durability, capacity, speed, and efficiency, enabling higher-speed, higher-capacity data transmissions.

C5ISR, which stands for command, control, communications, computers, cyber, intelligence, surveillance, and reconnaissance, offers critical capabilities for modern air power and multi-domain operations. Together, these technologies gather intelligence, process information, and maintain command and control by providing reliable communication, situational awareness, and network security across all domains—air, land, sea, cyber, and space.

CBM+ and Predictive Maintenance

Condition-based maintenance plus (CBM+) is a preventive maintenance strategy that monitors assets to determine when maintenance work is necessary. CBM+ improves legacy maintenance practices, which relied on pre-planned maintenance schedules, asset projected time to failure, and recommendations from the OEM. A more advanced strategy, predictive maintenance pairs continuous monitoring with asset health and repair history data analytics to identify optimal maintenance interventions, reducing costly unplanned downtime and asset failures.

Both CBM+ and predictive maintenance utilize electronic sensors and other monitoring equipment to collect data on the performance of assets and the health of their components and consumables. Through data-collection and monitoring, CBM+ systems identify anomalies, patterns, or trends that might indicate potential issues. Predictive maintenance adds machine learning to optimize maintenance interventions aimed at eliminating catastrophic failures.

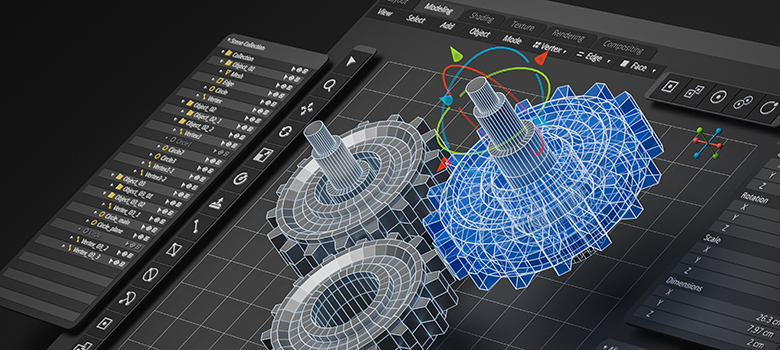

Digital Engineering

Across a wide range of industries, digital engineering uses digital models and tools as well as computational infrastructure to manage and integrate information, thereby optimizing product development, production, and sustainment. Digital engineering has numerous benefits, including improved collaboration and communication among key stakeholders, accelerated product development, flexible customization, improved error detection, streamlined manufacturing processes, and reduced costs. Specific digital engineering strategies include:

- Model-based systems engineering (MBSE), a formalized methodology that is used to support the requirements, design, analysis, verification, and validation associated with the development of complex systems.

- Digital threads enable the linkage of information generated from all stages of the product life cycle through a data-driven architecture of shared resources for long-term decision making.

- Digital twins, which offer integrated, data-driven virtual representations of real-world entities and processes, enable modeling and simulation of multiple predicted futures before synchronization with the real-world entities or processes.

The above capabilities and more can be harnessed by NCMS and its partners through the NCMS Digital Enterprise, which delivers a secure, multi-cloud digital ecosystem where multiple partners can safely collaborate.

Energy

Increasingly technologies are being developed to ensure energy availability and sustainability. Access to energy is the foundation of every economic sector, whether that energy is fossil-fuel based or clean and sustainable. NCMS has contributed to energy technology advancements, including battery storage solutions such as advanced Lithium-ion batteries, Lithium alternatives, solid-state batteries, and electrochemical flow batteries. Additionally, supercapacitor storage offers advanced solutions that store significantly higher amounts of energy. They work by storing energy electrostatically on the surface of two electrodes separated by an electrolyte and a porous separator, forming an “electric double layer” of charge. They have a much larger surface area and a much smaller distance between the electrodes than traditional capacitors, which allows them to store significantly more energy.

Environment, Health, and Safety

Innovations designed to improve protections for the environment and worker health and safety continue to proliferate. All US organizations must comply with federal laws and regulations regarding workplace hazards, employee protections, pollution control, waste management, and emergency preparedness. These policies—and the innovative technologies that have enabled improved compliance—are designed to prevent accidents, injuries, illnesses, and death, while promoting a safe and sustainable environment for workers and surrounding communities.

In the area of environmental safety and sustainability, numerous technologies enable the reduction or elimination of physical, chemical, and radiological hazards and their waste, with applications across a wide range of industrial and military platforms. In addition to supporting many new technology solutions, NCMS manages the Environmental Protection Agency's website for its Compliance Assistance Centers (CAC) Program, which helps multiple industries with key environmental compliance at both the federal and state levels.

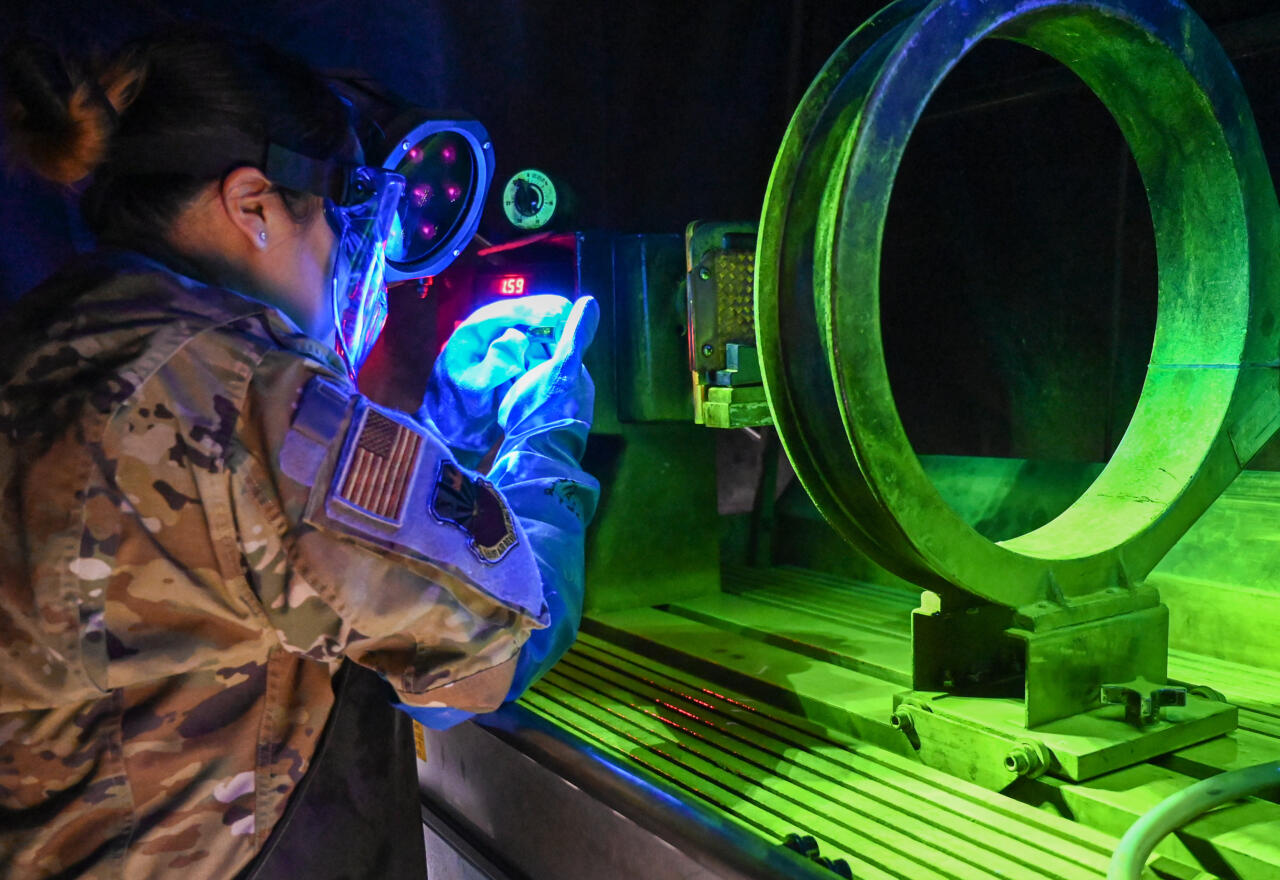

Enhanced Inspection/Metrology

Across many sectors, enhanced inspection and metrology ensure safe and reliable performance of equipment and other assets. Advanced metrology capabilities deliver automated measurement systems, non-contact measurement techniques, optical 3D scanning, X-ray computed tomography, and various systems enhanced by AI-fueled data analysis. Non-destructive inspection and testing (NDI/NDT) enable seeing past an object’s surface with such advancements as phased array ultrasonic testing (PAUT), 3D computed tomography (CT), electromagnetic testing, digital radiography, and thermography. Automated systems, robots, and drones provide inspection via units equipped with visual, thermal, acoustic, and lidar sensors. Whereas augmented reality/virtual reality, integrated with laser scanners, enable technicians to visualize measurement data directly onto the component being inspected, other inspection methods analyze visual data captured by cameras or sensors to detect anomalies.

Hardware

Advancements in hardware solutions happen every day, supporting a vast range of industries by increasing efficiency and reducing labor hours and costs. NCMS has long collaborated with government, industry, and academic partners to develop, validate, adapt, and transition innovations that deliver value on many levels, from simple and incremental to ground-breaking and revolutionary. Some of the hardware categories that NCMS has been directly involved in advancing include edge computing, manufacturing systems and equipment, microelectronics, portable machining tools, and more.

Materials Science

The continual advancement of materials science is critical to strengthening American manufacturing. Materials scientists seeking enhanced capabilities are studying and developing a diverse range of materials: metals, polymers, semiconductors, ceramics, energy materials, biomaterials, nanomaterials, and thin films to deliver properties not achievable through conventional raw materials. Further development of these materials benefits sectors including aerospace, defense, nuclear power, and energy.

NCMS has been catalyzing advancements on several fronts, including new materials development, advanced manufacturing methods, testing and qualification of advanced materials, and supply chain management for critical minerals and materials.

Robotics, Mobility, and Automation

Robotics, mobility, and automation technologies are transforming the manufacturing sector by driving improvements in efficiency, precision, quality, scalability, and more. Together, these innovations expand output and reduce operational costs by optimizing resource use, minimizing downtime, and reducing labor-intensive bottlenecks. Some of the more impactful advancements include autonomous mobile robots, which are intelligent robots equipped with sensors, cameras, and AI; collaborative robots, which are designed to safely work alongside humans through advanced sensors, force-limiting technology, and intelligent programming; and robotic exoskeletons, which are wearable, biomechatronic devices that augment human physical capabilities, including strength, endurance, and consistent motor function.

Software and Data Analytics

Related Stories:

NCMS is strongly committed to the continual advancement of software and data analytics designed to improve and expand operations. Throughout several decades of collaborations, NCMS initiatives have generated value for a wide range of business areas, including business process improvement, enterprise resource planning, human resource management, inventory management, and supply chain management.

Many organizations—including NCMS partners—now seek upgrades in specific capabilities for their operations, targeting areas such as:

- AI integration into software development to streamline the development cycle, generate code, detect and fix bugs, automate testing, generate documentation, enhance security, modernize legacy code, and more

- AI and ML models that are trained and applied on prepared data to extract insights, patterns, and trends for more informed decision-making

- DevSecOps, which stands for development, security, and operations, a framework that integrates security into all phases of the software development lifecycle

- Predictive analytics uses historical data to forecast potential scenarios that can help drive strategic decisions

- Synthetic data—artificial data designed to mimic real-world data—offer a useful way to produce an almost unlimited amount of data, with statistically relevant information, without exposing private or sensitive data

Related Stories:

Workforce Development and Training

The US manufacturing sector faces a critical and growing shortage of skilled workers, particularly given the rising rate of retirement for the baby boomer generation. In addition, the pace of technological change has presented additional challenges to the workforce like never before. With an estimated 3.8 million new workers needed in the American manufacturing sector by 2033, nearly 1.9 million of those jobs could remain unfilled if workforce development and training needs are not met.

For manufacturers, attracting and retaining talent is a top business challenge, especially in the face of new and emerging technologies: AI/ML, digital engineering, data management, cybersecurity, robotics, automation…the list of positions requiring specialized technological training grows by the day. To solve this problem, it is critical for employers to identify technological requirements, match them to worker skill sets, and collaborate with education and training facilities to create a pipeline of technical talent ready for work.

In addition, a great deal of new technology has been developed that can enhance on-site worker training capabilities: augmented reality (AR), virtual reality (VR), multi-media training manuals, and mixed reality systems for consultations with off-site experts are just some of the areas on which NCMS has collaborated.